high-speed rail aluminum die casting accessories

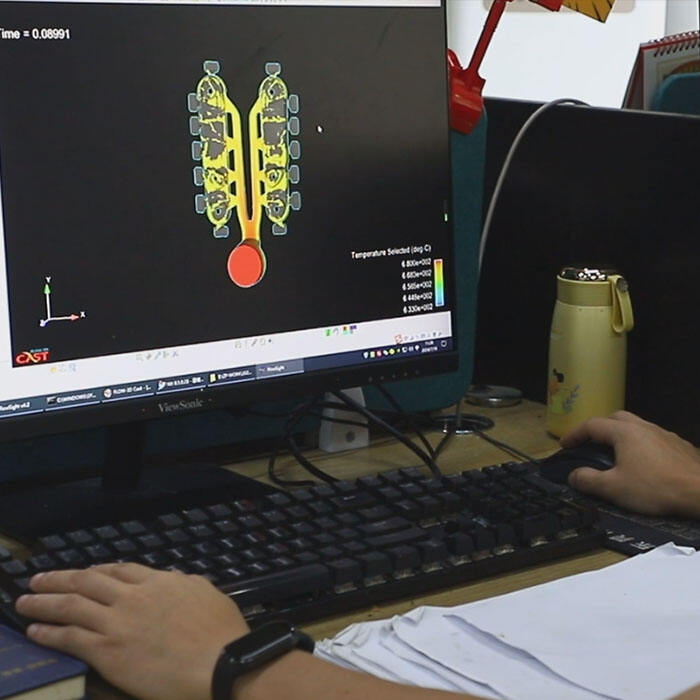

With these powerful aluminum die casting accessories, the eventual aim is to provide a high performance product that meets the world's highest quality standards in protection and reliability specially tailored for a high speed trainenvironment.The accessories are highly necessary in maintaining the structural integrity and performance of the trains.Support structures, housing for electrical components, and various bits and pieces that make the train go faster are all part of the functions for these accessories.Having technical features such as high-strength aluminum alloys that offer 12 times the strength-to-weight ratio of steel, precision casting technologies ensuring that internal structures exactly conform to complex design drawings; surface treatments to improve wear resistance.Taking the frames, seats, brackets, covers and other accessories on high-speed rails as an example, these accessories are widely used themselves. They are ultimately essential to assure that this market will have a good future.