aluminium casting foundry

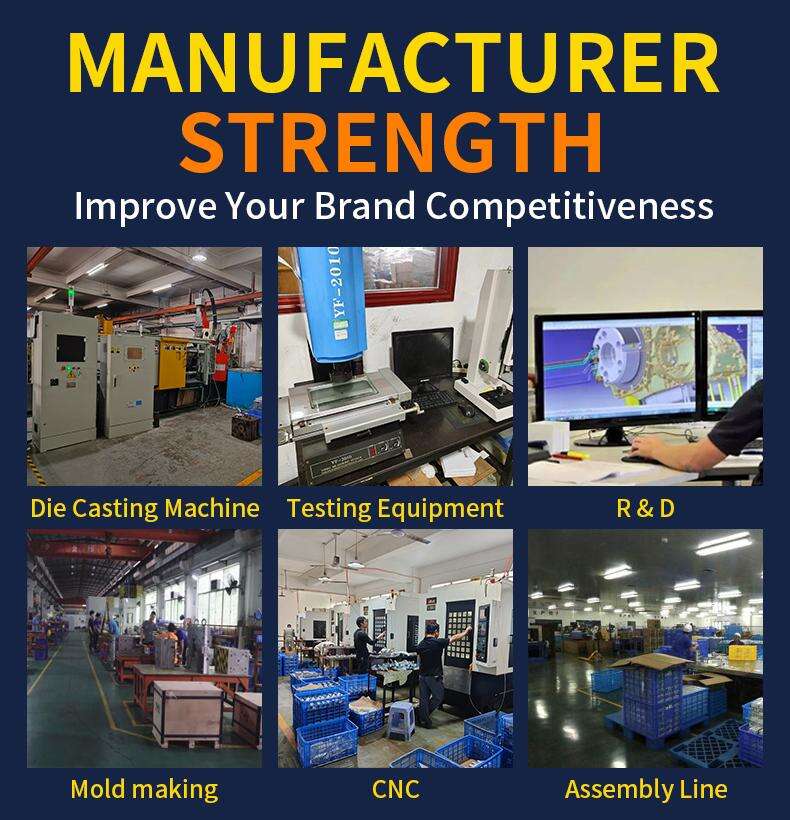

An aluminum plant is a professional place of manufacture, in which hot aluminum is poured into metal molds engineered for this purpose in order that the resultant product may be cast as required by this first shaping process. The main tasks of an aluminum plant are melting the metal, making the molds, casting and finishing products. Technical features such as state-of-the-art melting furnaces, precision mold-making processes, and automated casting systems have become an integral part of its production activities. The plant provides a wide range of cast parts and components used in industries from automotive to aerospace, from construction to consumer goods. With the wide-ranging application, use of advanced materials and the necessity of producing light yet strong products, the light metal plant is indispensable for production of highly accurate aluminum parts that correspond to international standards.