I. Introduction

Among the many manufacturing processes that exist, die Casting is a beneficial process used to produce parts in large quantities. Die casting is a metal casting process that employs the use of molten metals, coercing into forms through high pressure in which it will then solidify and create shape.Developed as an economical way to produce large quantities of product, die-casting excels because multiple casts can be made from a single mold with extremely accurate results. This article will walk you through the reasons why die casting is such a popular manufacturing method across industries.

II. Advantages of Die Casting

A. High Production Efficiency

Die casting has fast cycle times, and parts can be produced in a matter of seconds. Given that die casting is among the fastest processes of all for producing parts, this speed advantage, coupled with high-throughput and throughput performed machining operations work to minimize downtime —which often happens when demand exceeds supply.

B. Accuracy and Dimensional Tolerance

Because they are processed by Casting Molds, one of the characterizes is Precision for Die Castings. Using this technique ensures parts are produced with high accuracy and repeatability needed for applications that require precision fit and function. The accuracy of die-cast parts needs minimal post-casting machining, simplifying production.

C. Design Flexibility

The precision of die casting gives it an advantage over most other forms of production-capable casts, enabling much more elaborate designs than can be produced in alternative processes from molten metal. Designed to handle thin-walls, fine detail and internal complexities of parts that traditional manufacturing methods currently have difficulty replicating making the process more suitable for a wider range of applications.

III. Material Suitability

A. Popular Die Casting Materials

Die casting is versatile, and it can handle a broad range of materials. Aluminum, zinc, magnesium and copper alloys are some of the most common materials used because each possesses unique combinations of properties for specific end applications it can serve.

B. Some Of The Material Properties Which Makes Die Casting Famous

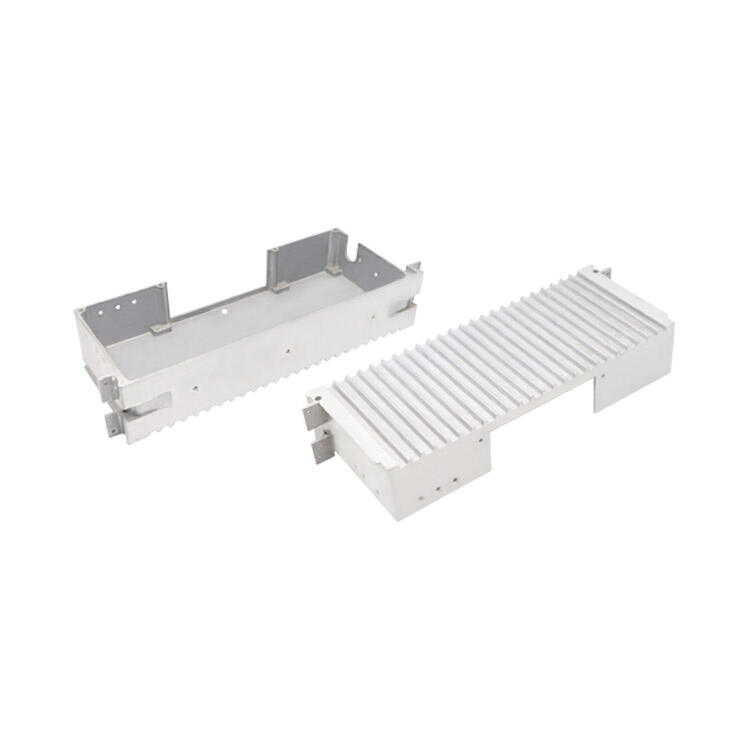

The Car is made up of different kinds of materials which can be used as die casting but the choice of material in die casting does not only depend on what you can cast it also depends upon the quality that material brings to the final product. Aluminum die castings are lightweight and have good thermal conductivity making them a good choice for automotive parts or heat sinks on electronics, to name but two possible uses.

IV. Cost-Effectiveness

A. Lower Tooling Costs

Die casting — The reusable nature of the dies means that die casting frequently enjoys lower tooling costs when compared to other methods. The die cost is the initial investment, but the per part costs can drastically fall at high production volumes.

B. Reduced Material Waste

Because die casting is so precise, it uses less materials which makes the whole production process efficient. Not only does this decrease costs, but it also fits in with the type of green manufacturing process that is becoming increasingly common.

C. Mass Production Economies of Scale

Since die casting molds can create parts in large volumes per hour, they are an economic manufacturing method beyond a reach using conventional processing methods which lead to labor and material costs absorbing disproportionately.

V. Industry Applications

A. Automotive Industry

The automotive sector is the most common end-user, used to fabricating die casting as engine parts and structural components. The fact that die-cast elements are both lightweight and robust is ultimately decisive for saving fuel and enhancing performance.

B. Aerospace Industry

Die casting is applied in aerospace for lightweight parts that are required to work under very high conditions. Their precision and strength of die-cast parts render then perfect for use on aircraft as well a spacecraft components.

C. Consumer Electronics

Consumer electronics, for example always need precise parts that can be produced in very large quantities: die casting is perfect. Die-casting processes are used mainly for the die casting of housings and small precision parts

VI. Environmental Considerations

A. Energy Effectiveness in Die Casting Process

This process is a extremely energy-efficient than other casting processes such as sand or investment molding and can help to reduce the carbon footprint of manufacturing.

B. Material reuse and sustainability

Due to this * Most die casting materials are recyclable and allow for a circular economy that is also beneficial as most of the material can be recycled over again in an industry leading humanitarian contribution.

C. Die-Cast Product Lifecycle Evaluation

Indeed, a critical review of the lifecycle assessment results for die-casting products easily highlights its positive environmental profile across production to end-of-life recycling stages.

VII. Quality and Precision

A. Comparison to Other Manufacturing Processes

Not only does die casting give this combination, but it is also remarkably more rapid than the likes of forging or machining. Forged parts may be stronger than die castings, but examples above prove that design flexibility and cost savings can also side on the die casting method. Mechanical processing have a high accuracy, but are more expensive and slower.

B. Die Casting Quality Control

Die casting is inherently repeatable and the process allows for implementation of strict inspection protocols to maintain high part quality, enabling better control on die casting quality.

VIII. Limitations and Solutions

A. Material Limitations

It is versatile, but not ideal for all materials Allow me to explain. But, material science advancements continue to increase the set of materials that are candidates for die casting.

B. Design Constraints

Die casting limitations regarding draft angles and core movements can be overcome with creative design or the aid of engineering principles. C.

C.Defeating challenges by improving processes

The die casting technology has improved significantly over the years evolving it into an efficient technique and process optimization which makes reliable by overcoming challenges such as porosity, dimensional instability etc.

IX. Future Trends and Innovations

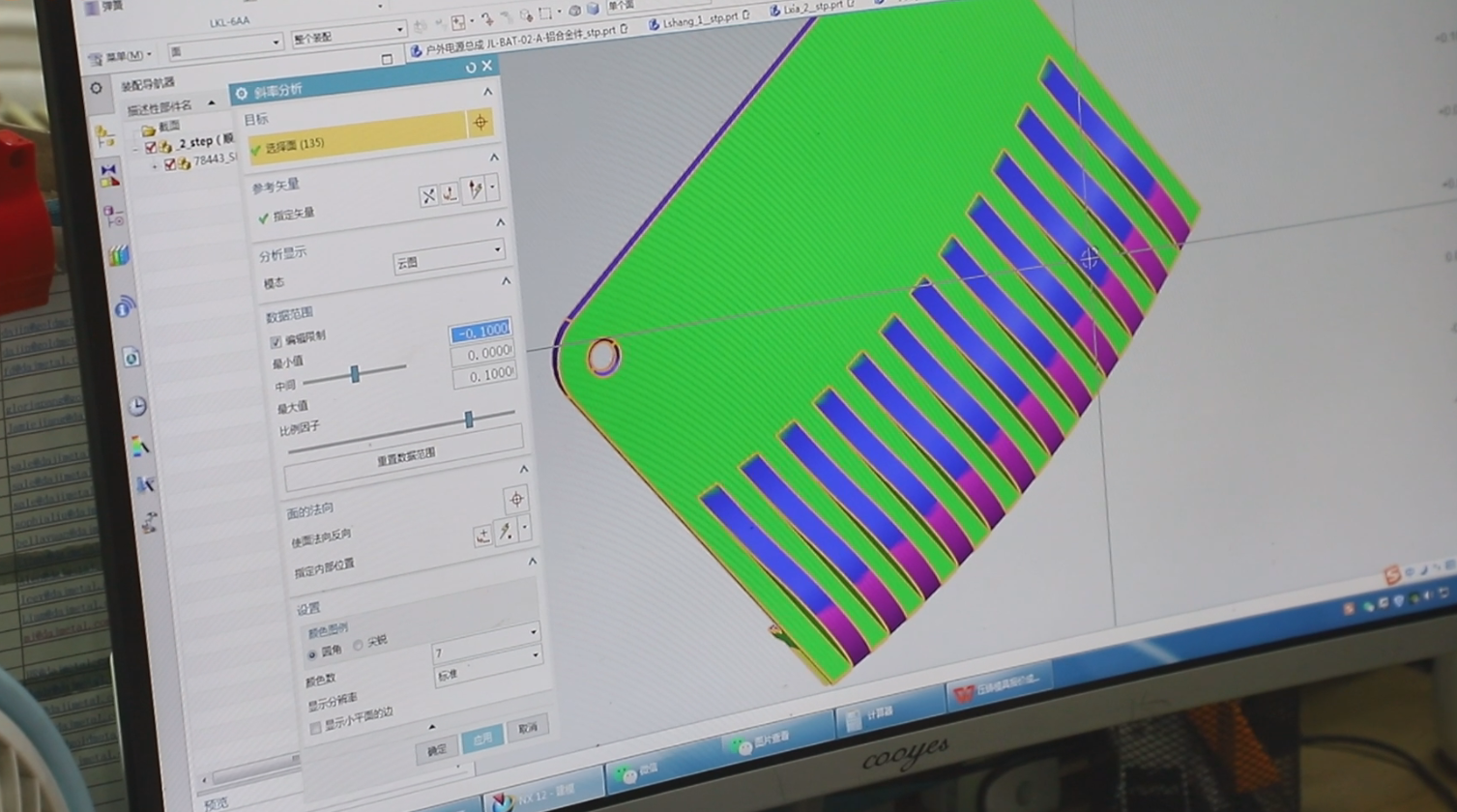

A. Technological Upsurge in Die Casting

For die casting, this usually means simulation software in design and automation on the shop floor—even at a processing level.

B. Adoption of New Materials

The die casting process is having new materials developed and incorporated like high-strength alloys, composites to make the applications even wider than before.

C. Integration with Other Manufacturing Techniques

Die casting is becoming further integrated with other manufacturing technologies, for example 3D printing tooling or direct metal laser sintering (DMLS) complex cores to allow new innovative opportunities.

X. Conclusion

Its popularity in manufacturing speaks to its adaptability for the 21st-century industry. Efficiency, precision, materials, price point and adaptability to any applications make it a formidable in manufacturing industry. With technology increasingly improving and bridging the gap between traditional die casting techniques, rapid tooling technologies will continue to gain traction as an essential part of a broader vision for manufacturing.