lighting die casting mold foundry

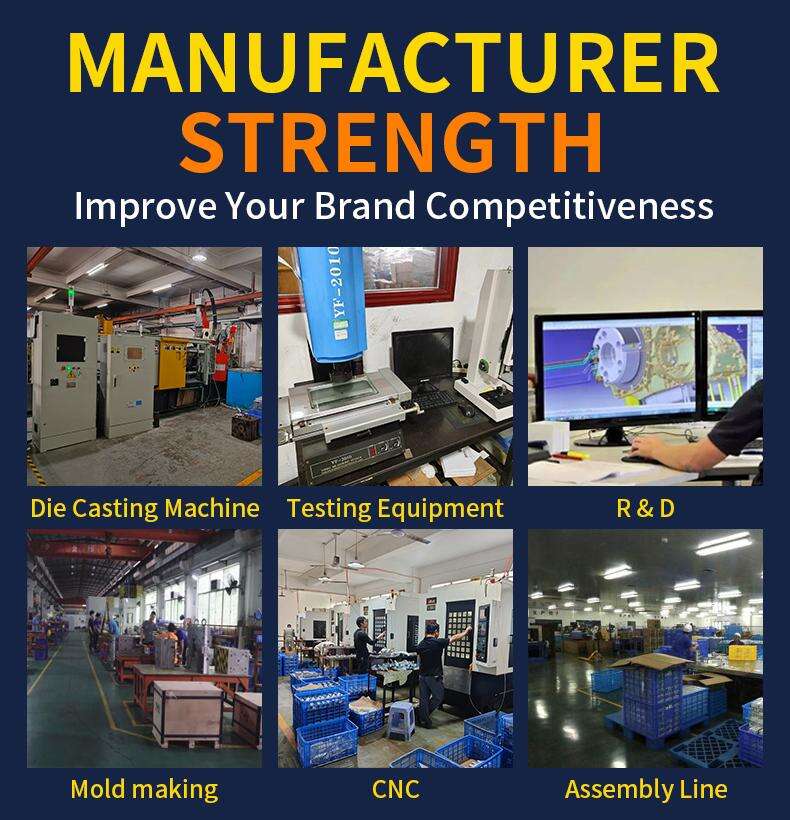

The Lighting Die Casting Mold Foundry is an integrated specialized manufacturing plant. It's a key player in the production of light fixtures for lamps and lanterns. With the latest technology, this foundry for casting a die is able to design and produce precision molds used in the die-casting process. These molds in their turn have a decisive effect on whether different kinds of metals are given shape suitable for doing tasks suitable for light fixtures or not. Technical features of the foundry include CAD/CAM software for accurate mold design, high-precision CNC machining centers to manufacture the molds themselves and advanced testing equipment in order to guarantee quality standards are always maintained. The products of the lighting die casting mold foundry are used in a great variety of ways over this country-from architectural lighting and streetlights to residential and commercial lightings, thus showing what use there is with this development of manufacturing activities.