Introduction

Custom die Casting is a process of precision manufacturing, crafting intricate metal components from molten metal injected into special- purpose molds. One day, or the time from the start of a project to delivery, is a key criterion for modern manufacturing companies who appeared and are still operating according to market needs and customer demands. This article will give a detailed look at lead times for custom Die casting projects at every point from kit design through delivery.

Stages of a Custom Die Casting Project

A custom die casting project generally consists of several stages: initial consultation and design; tooling and mold development; the actual casting process; post-casting processes quality control; and finally delivery.

Design Phase Lead Time

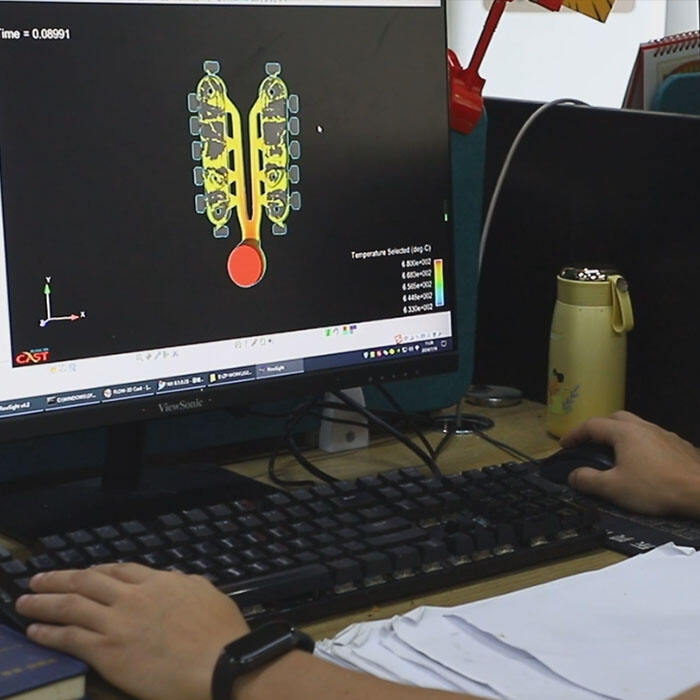

In the design phase, conceptualization and CAD modeling are the first steps: engineers convert customer needs into a detailed 3D model. Next comes material selection based on cost, weight and strength factors. While this phase may be extended by client feedback, usually it lasts between a few days and several weeks depending on how complicated the project is.

Tooling and Mold Creation Lead Time

The creation of tools and molds is a key step in production, the amount of time it will take depending greatly on how complex and what material the mold itself. Refers: simple moulds can be ready after 2-4 weeks; but more intricate designs may take 3-6 months. The mould making process involves CNC machining, electroforming and assembly, not all fully automated-that requires skill.

Die Casting Production Lead Time

Production starts once the mold is ready. First, parts are loaded into the machine and then a test run is made to 'debug' the process. When all is set up, full-scale production follows. The time it takes to manufacture semi-finished products greatly depends on part complexity; the volume of the order; and the efficiency of die casting machines themselves. Orders ranging from small to medium size will typically take anywhere between a few days and several weeks for production.

Lead Times for Post-Casting Processes and Quality Control

In many cases we need to perform all sorts of post-casting processing, including finishing machining and assembly so that each element can be given exact dimensions and surface treatment. Quality control and testing to be sure properties meet specifications requires time, however it varies from project to project depending on the extent of these procedures. This process can add seven days or more, depending on the complexity of your particular job.

Final Inspection and Delivery Lead Time

Here the last stage is a careful inspection, packaging and preparation for delivery. The stage is relatively rapid, generally only about four days, but great care must be taken to make sure prior to delivery that customer quality expectations are met in each part.

Factors affecting lead time

Several factors affect lead times in custom die casting projects, including part design complexity, order volume, material availability and production capacity. Long lead times can follow from complex designs with tight tolerances and intricate features, while large order volumes--which require more production time--will also take longer.

Strategies to Reduce Lead Times

Efficient design and communication practices, state-of-the-art production planning, advanced equipment and automation, and effective quality control measures--these are some of the ways that manufacturers can deal with lead time issues. Collaborative efforts between design, engineering, production teams also ensure faster progress.

Conclusion

For custom die casting projects, lead times typically range from a few weeks in length for simple projects to several months for more complex work. By knowing what factors affect lead times and implementing strategies which can tighten up each stage of the process, manufacturers are able to ensure that projects get done efficiently and delivered on time. In the rapid pace of today's manufacturing, effective lead time management is a must for keeping competitive.

Table of Contents

- Introduction

- Stages of a Custom Die Casting Project

- Design Phase Lead Time

- Tooling and Mold Creation Lead Time

- Die Casting Production Lead Time

- Lead Times for Post-Casting Processes and Quality Control

- Final Inspection and Delivery Lead Time

- Factors affecting lead time

- Strategies to Reduce Lead Times

- Conclusion