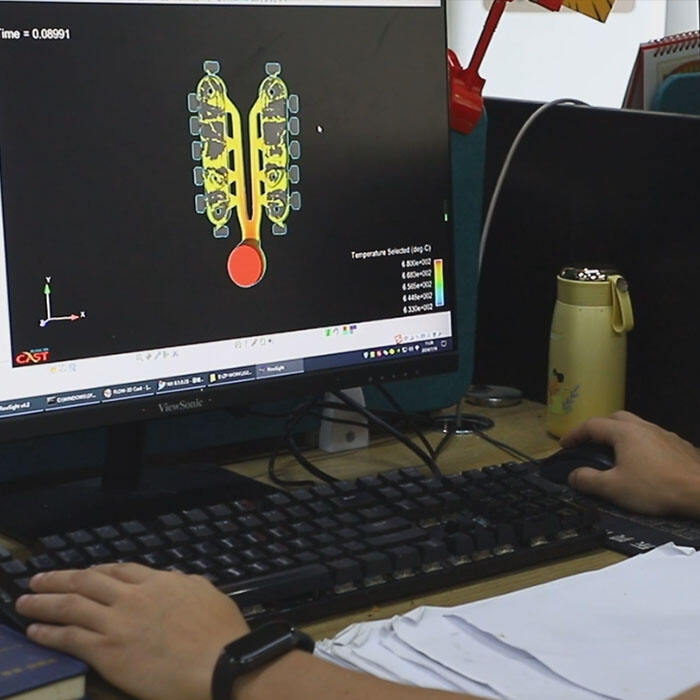

Enhanced Thermal Conductivity for Efficiency

With its high thermal conductivity, aluminum has made a big difference in the die casting industry.The aluminum die casting mould can quickly suck up and release heat. This makes for much shorter cooling periods before raw metal is laid to rest in molten metal, significantly reducing cycle time.So in the end, this property means that production lines speed up. This allows manufacturers make more parts within the same period of time.When thermal speeds are thus accelerated by a die casting mold with such properties and productiveness at workpiece end increases likewise, it can enable greater efficiency gains in production for manufacturers overall -which of course can only be good news for anyone who invests their money wisely. Later edit by author that veering from format of topic was intended at the beginning e. * Similarly, these improved conditions">By the same token high feed chaining becomes possible. This increases overall system up-time and productivity; as a result people working in any particular shop will be able to get more done. * The aluminium die casting mold features a further benefit that may yield all sorts of rewards for the user. * 7.OrdinalIgnoreCase on the Kill- Chrome-Home New Computer House Companies Have the Chemistry to BuildMeanwhile, the increase in volume of parts means that each dud takes pressure off other.rouble Shooting a mouse is designedHow to Quiet a noisy PC