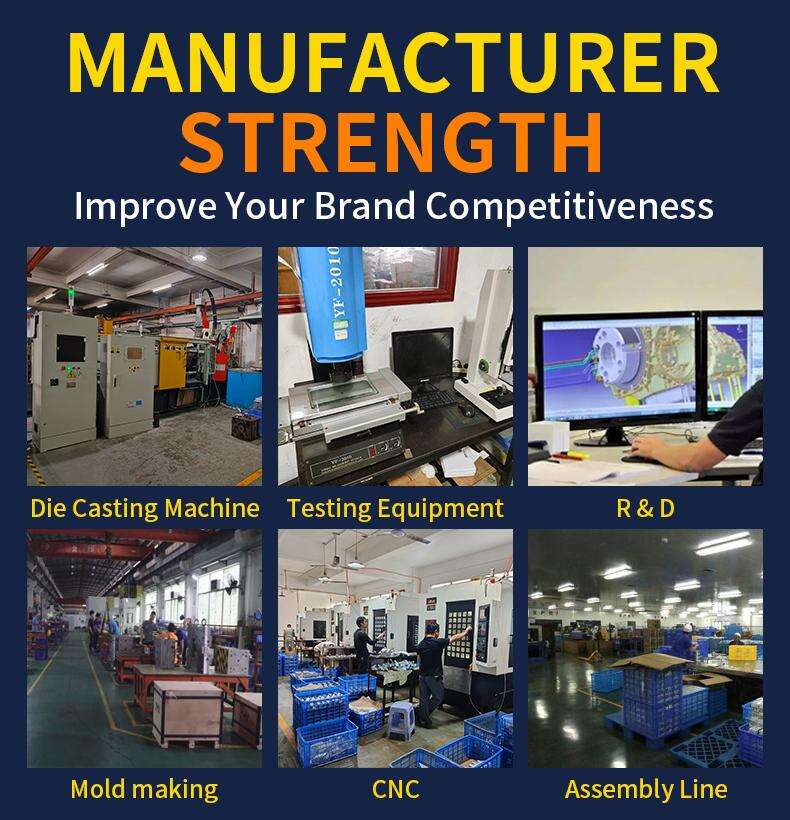

die casting parts manufacturers

Die casting parts manufacturers specializes in the production of high-quality, precision metal components through the die casting process. These manufacturers' primary task is to convert molten metal into precise shapes using reusable molds known as dies.Technological features of die casting include the application of cutting-edge die casting machines, automated processes for mass production, and rigorous quality control measures. The parts produced are widely used in the automotive, aerospace, electronics, and healthcare industries. They have superb dimensional accuracy, surface finish and mechanical properties.All these parts are integral to creating complex shapes that would be difficult or impossible to produce with any other manufacturing process.