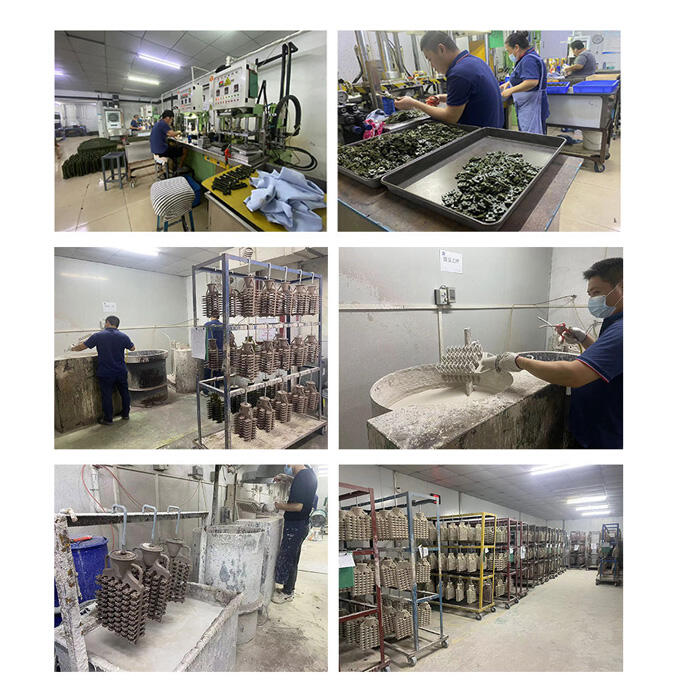

high precision die casting

This sophisticated manufacturing process for producing highly accurate and excellent finish components is an intricate procedure in which molten metal is injected into a die by high pressure (≥100 MPa) The main purpose of open precision die casting is to manufacture complex shapes which are difficult or impossible to realize by other or less expensive methods, maintain tight (usually within 0.001 inch) quality control and mass produce with unvarying consistency. Use of specialized dies and advanced casting machines foundry get indescribably beautiful details and precision that traditional methods can't compete with. This process finds extensive applications in fields such as automotive, aerospace, electronics, health care, where components must meet strict quality standards