magnesium casting companies

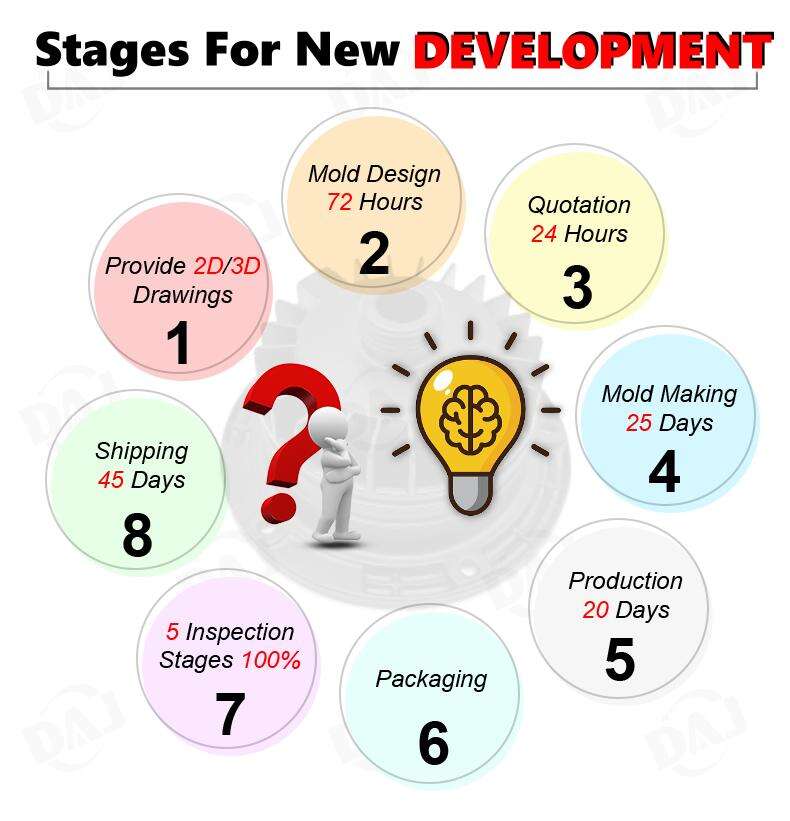

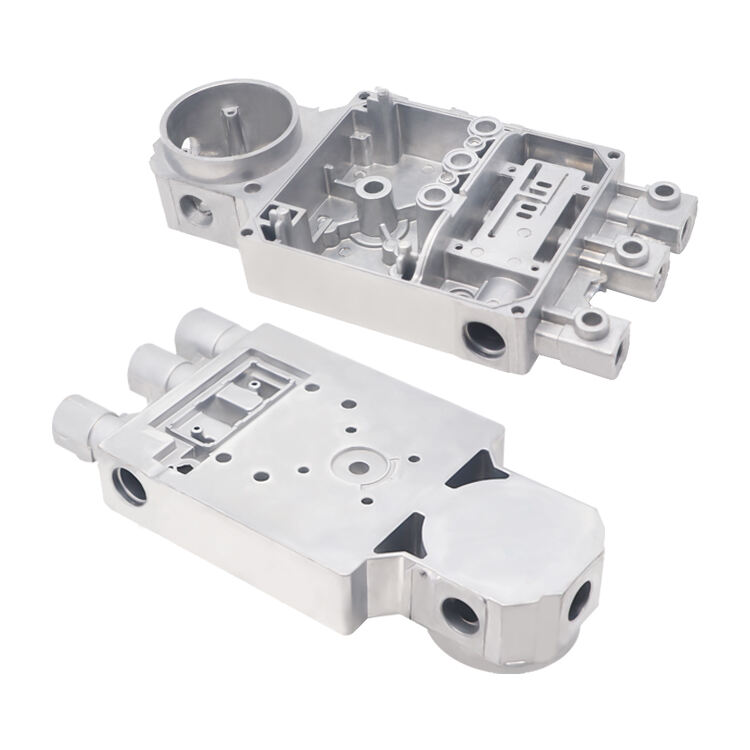

By casting, magnesium casting companies innovate and produce high-quality components of Mg alloy.Casting stores comprise some of these essential functions: making moulds, melting and pouring magnesium alloys, as well as finish work on casting products.Technological characteristics include advanced forming methods such as die-casting, sand casting, and permanent mold casting that guarantee an accurate structural bothers.With modern machinery and strict quality control systems, the factory carries out regular inspection and preventive maintenance programs.Reverse-engineering of vision inspection equipment for Higher quality vision detection results.In the 'fifties, magnesium casting found widespread applications, from automotive lightweight parts to aerospace durable compone nts deriving from reduced fuel consumption and inereased performance.