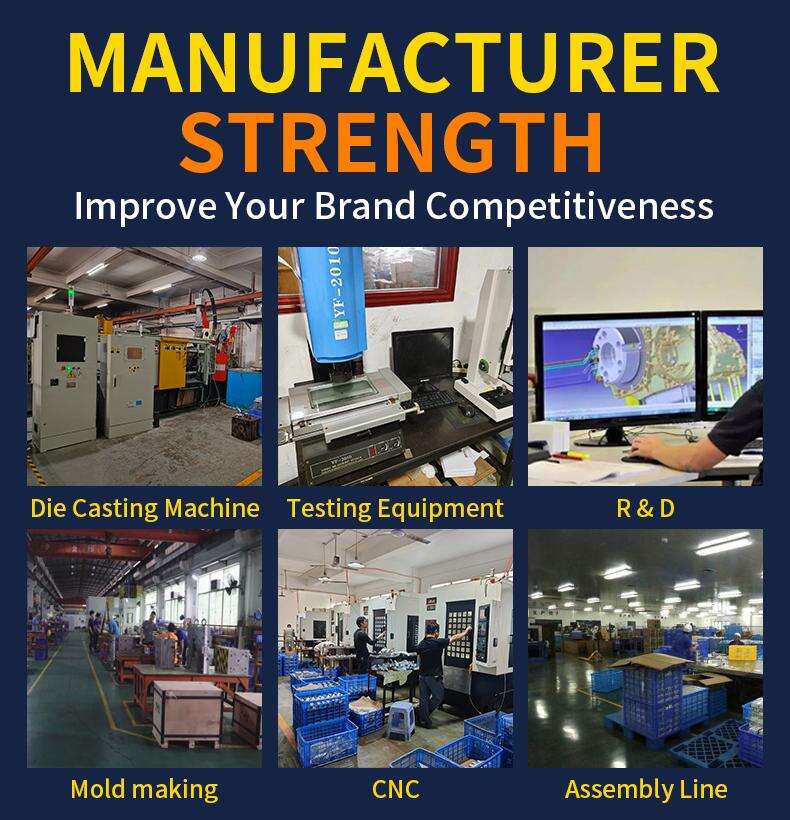

high pressure cast

The high-pressured cast process is an advanced manufacturing process to produce high quality, high precision parts which are of excellent surface finish and shape accuracy.The main function of it is that it gives us the ability to produce complex shapes and intricate details such as can not be created with conventional casting methods.COMpared with traditional sand casting and low-pressure die casting, the high pressure cast has control features that are totally different. For instance, a high-pressure fluid is directed into a die so as to fill cavities in the mold, then material is distributed uniformly throughout plastizaing products that are sintered in compact powder form whatever the shape or size.Typical applications include producing components such as engine parts for automobiles, turbine blades and medical instruments in industries from the automotive sector to aerospace, from healthcare instrument manufacturing fields all over the world but not limited China!