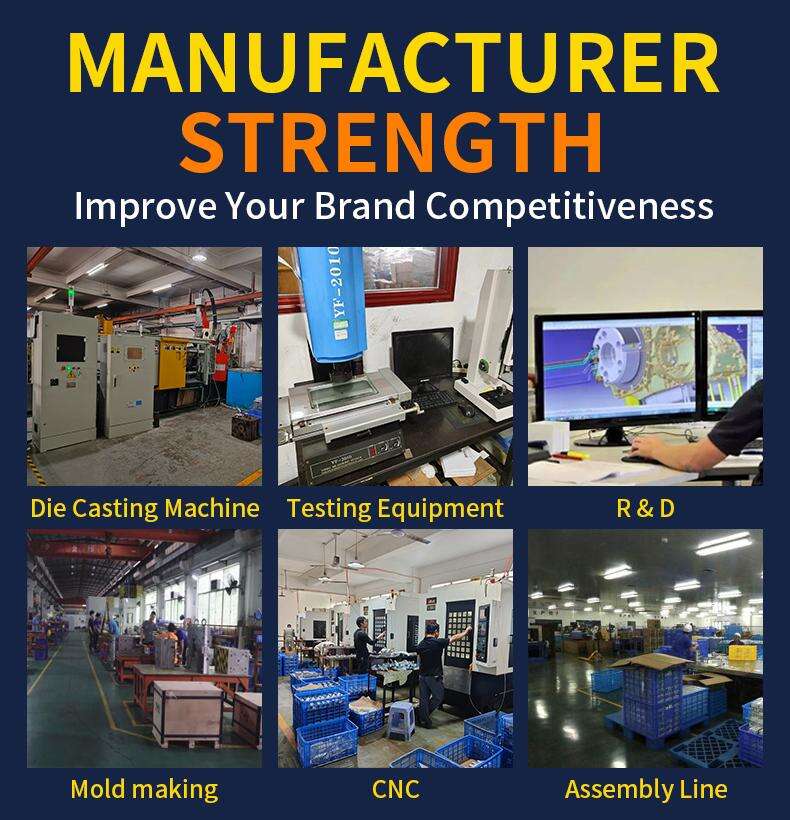

industrial casting service metal parts

In the production of metal parts, industrial casting services is a key way to get precision and efficiency. The practice necessitates pouring molten metal into a mold and letting it set, leaving you with an intricate product that is finished. The main functions of industrial casting services include shaping metal components with a high level of accuracy and consistent dimensions. This is especially critical in industries that demand complex geometries and tight tolerances for their output. Technologies used in industrial casting services--such as advanced alloys, computer-aided design and automated processing--all contribute to the quality and reliability of the castings. Applications can be found throughout the automotive, aerospace and construction industries, as well as in myriad others, making industrial casting services an indispensable part of current manufacturing processes.