electrical products die cast accessories

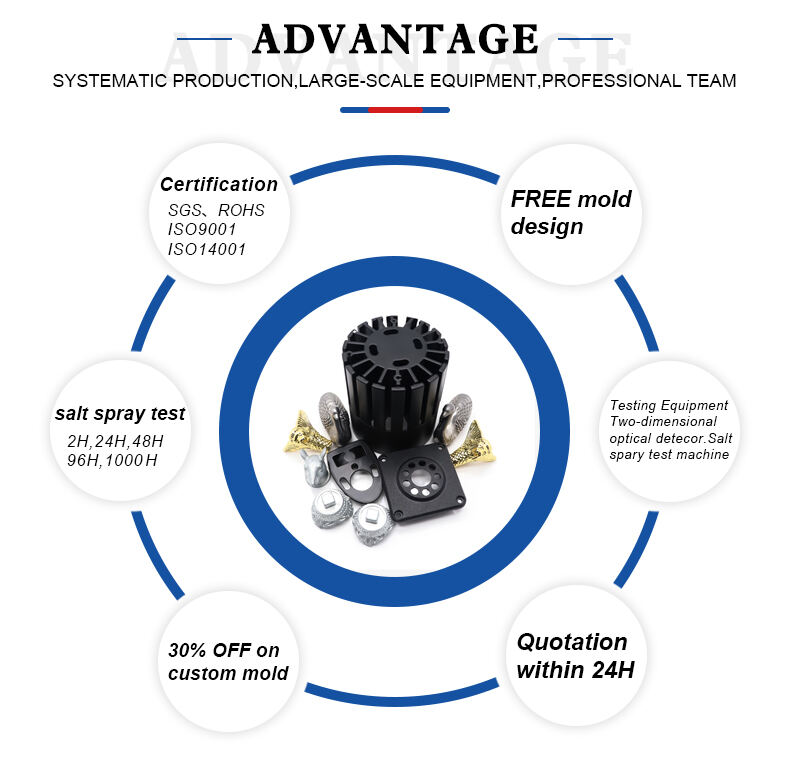

The heated metal is then pumped until it fills all the mold lines with molten material.Binding them up tightly, there once was a popular model that made use of short cast accessories as its major selling point.ally made by die cast process, these accessories are typically made from an alloy of aluminum, zinc and magnesiumThey have a number of functions. These are: Creating strength in the structure Improved electronic connectivity Protection for sensitive electronic componentsThe technology of such accessories involves thin material form and high precision complex shapes due to advanced die-casting techniquesIn automotive industrial, you can find all the locally made automobiles which use these type of components. Among others, they find application in aircraft engines as well as power plants for that same reason. Combined with that excellent performance is another critical factor this feature for information exchange [2] From electrical enclosures to connectors and heat sinks 21 diecast accessories play a crucial role in the performance and longevity of electrical products.