brass die casting

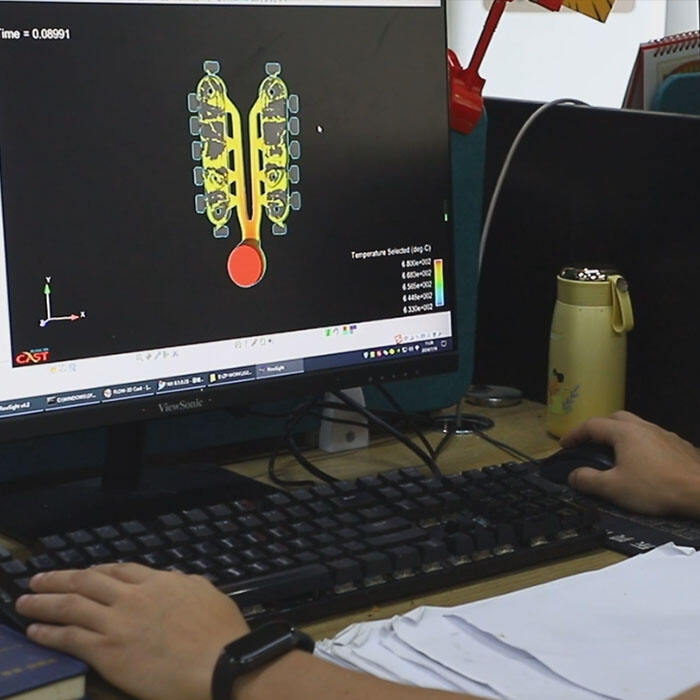

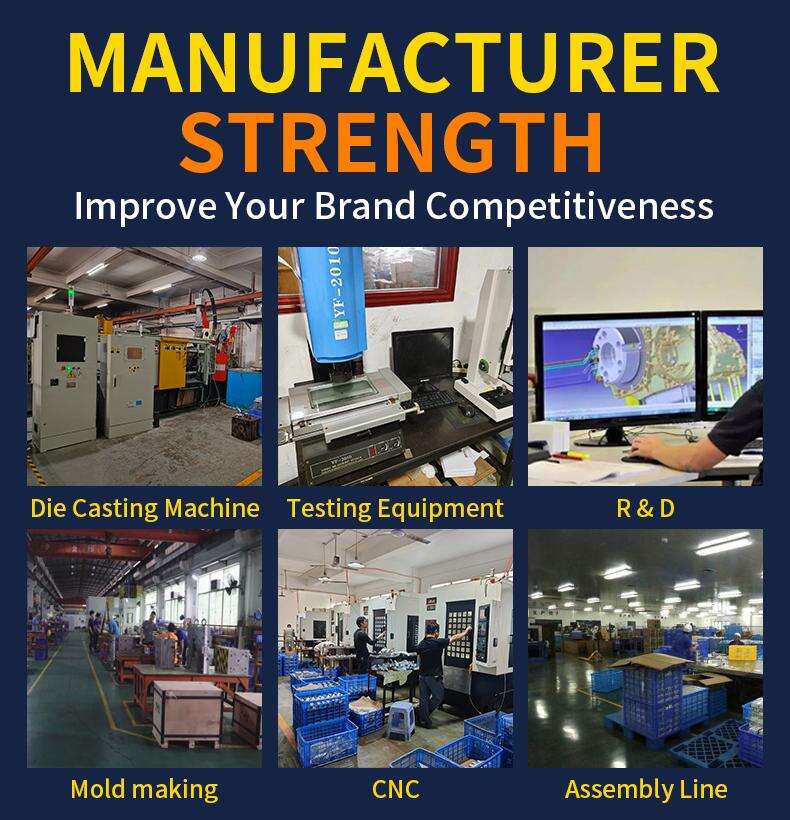

Precision metal processing can be achieved when brass solidifies into a Precision brass Die Casting that is injected onto the former component's depression through a stage of copper injections. The important role is not only to produce high-quality components but also to shape metal parts with high accuracy and complexity, rapid production rates, as well as the ability to produce complex shapes that are impossible or extremely difficult with other techniques of manufacture. Technological aspects of brass die casting includes the employment of high-pressure injection to ensure that the metal is filled uniformally in its mold and has high dimensional precision, as well as an exothermic parting line. Once cast, these parts usually only require some grinding rather than machining. This will save material and time on a lot of components. The Brass Die Casting market encompasses many application areas, including industries such as automobiles, electronics, hardware, and plumbing. As these fields increasingly have emerged into a new phase or newly begun to give out prototypes (therein with vast application ongoing), demands exist for components that appear attractive aesthetically durable--these demands cannot be met by more traditional machining in which one cannot feed into a machine two hundred or more different tools in order to dress a single.Properties The applications of braizedName of Adjective Die Casting are wide and varied, incorporating industries such as auto, electronics, hardware, plumbing, and more where durable and elegant metal components are needed. However, not all applications are equally well-known because the direct results of making things with chalde materials obvious from a cursory glance and this has led to a certain ironic neglect for such manufacturing in the formative years while everything was still being done by hand.