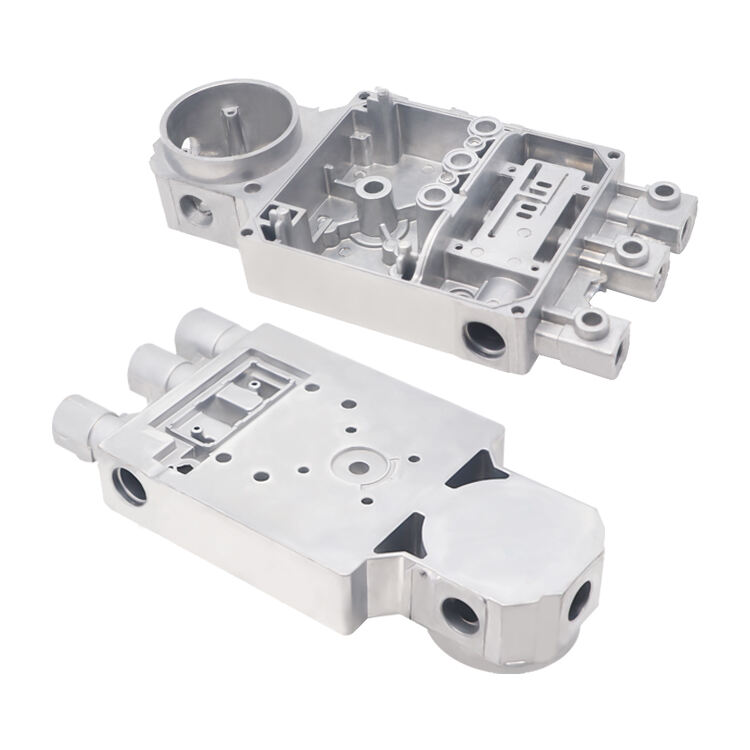

Precision and Complexity in Design

In auto die-casting, complex geometries and close tolerances can be handled from the very start Another equally important advantage is the precision of die-casting technology This indispensable feature makes for smooth final assembly procedures Eliminating finishing and those subsequent problems which may exist in a precision die casting part This precision at die-casting ensures that each component will fit perfectly into its final assembly, at once reducing need for additional finishing and the time required to assemble For manufacturers, this means considerable cost and time savings; for consumers it brings good-looking products which are also functionally better manufactured Erikson said Inthis state of the art manufacturing environment, every individual part is performing exactly as it was designed to factɜn