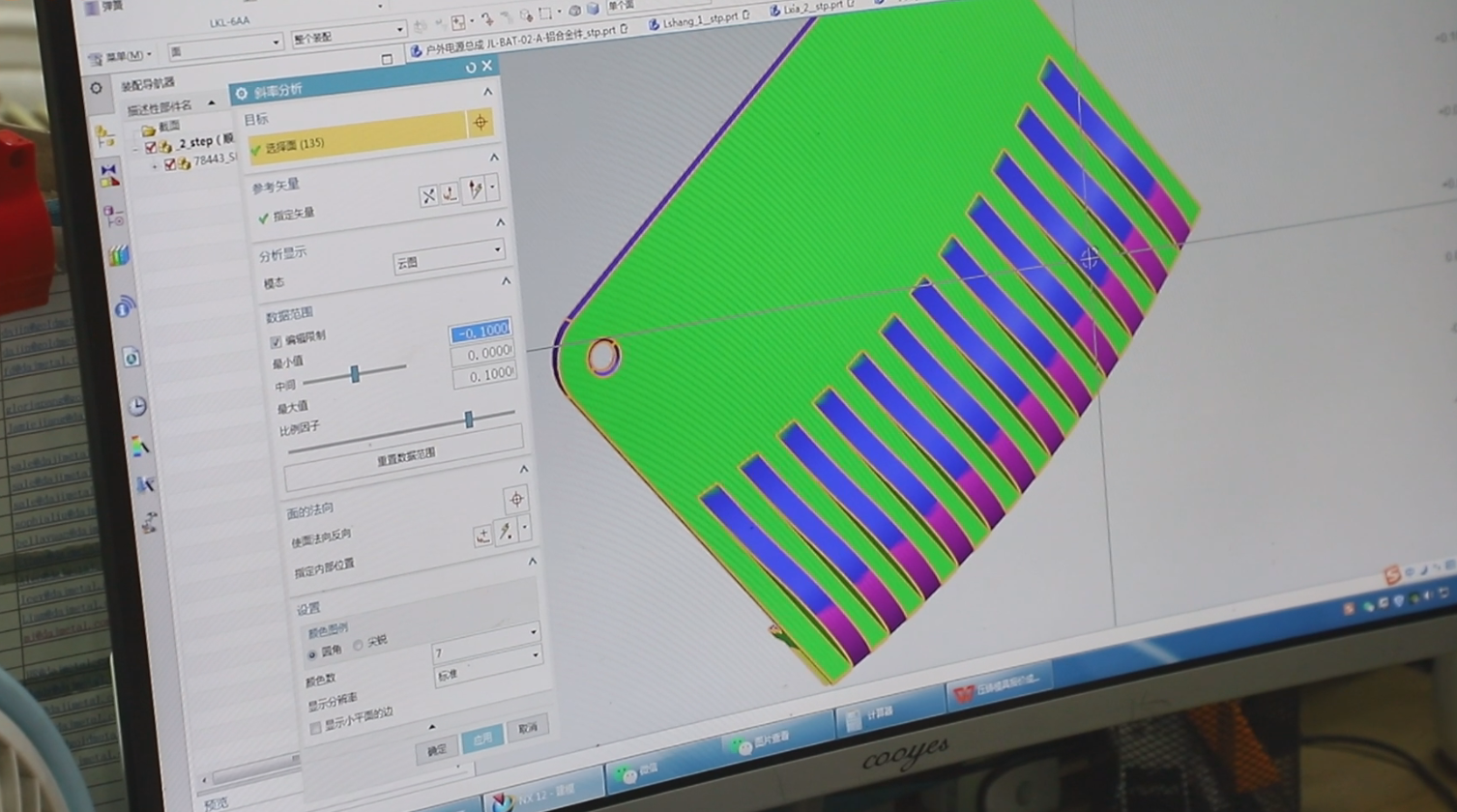

Material Efficiency and Cost Savings

Custom metal casting also offers another important advantage: the conservation or efficient use of materials required. During the casting process, molten metal is poured directly into the mould so it is used much more efficiently than with traditional machining methods, which generate a tremendous amount of waste scrap. This not only reduces material costs, but also lessens environmental harm. For companies, that means saved money--and a cleaner production process to boot. In today´s ecologically conscious society, this can only be seen as good business sense. To roll products has extra costs not directly related to what the customer gets; there are losses from bad quality and wastage in production line processes as well. But these insults to efficiency and waste are also opportunities—the materials used represent potential loss of money which in rk could be made into profit instead. For those companies looking to improve operating economics while maintaining high standards of products output from particular types of equipment, the efficient use of material is a big plus.