die casting companies

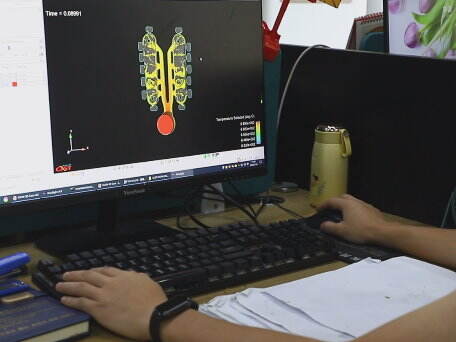

Die casting companies are engaged in the manufacture of metallic objects. The process takes raw molten metal under pressure and injects it into a mold cavity. That procedure known as Die-casting produces complex parts with fine detail, continuity and repetition. The main functions of die casting companies include part design, mould making, and high-speed injection. Technical features include the use of automatic systems, advanced alloys, and precise temperature control. This is a process to produce parts with good surface quality and dimensional conformity. Die casting applications range across an wide variety of industries such as auto, aerospace, electronics and more besides. They contribute essential components like engines blocks, gearboxes cases and housing for electronic equipment.