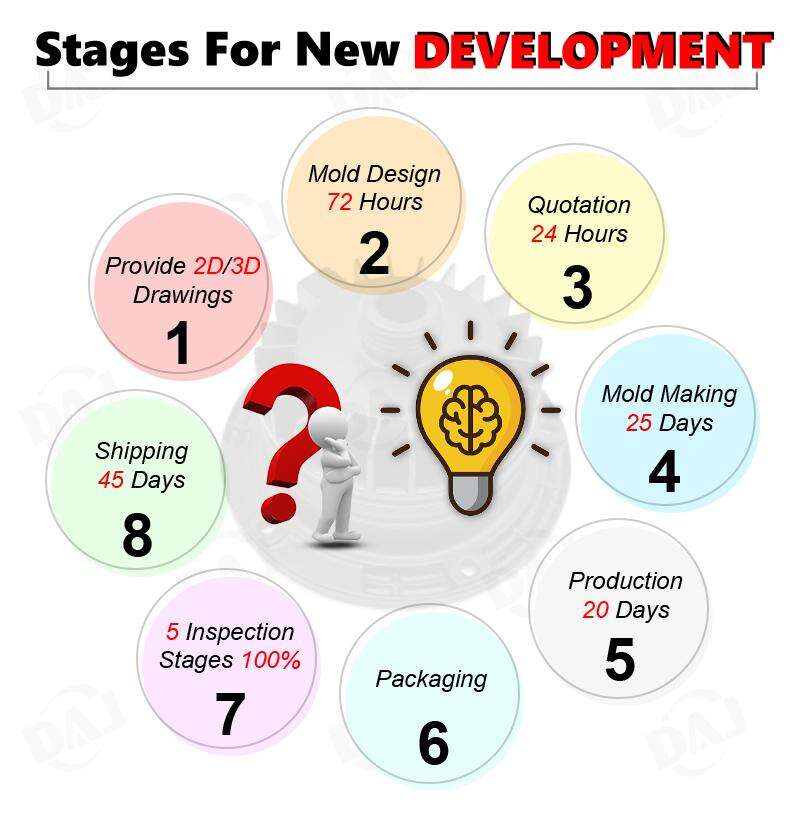

aluminium high pressure die casting process

High pressure die casting can be used to produce the aluminum found annually by arriving visitors. This method is capable of making parts with precise dimensions and intricate shapes. High pressure die casting comprises three essential steps: first comes production of the part's configuration, next the measuring, and finally prepolishing as necessary. Features of this process include the use of specialized machines for die casting, quick cooling rates due to high pressures in lowering aluminum phase transitions, and automated systems to increase productivity quality. The applications for this type of die casting are widespread and include many industries. ranging from automotive and aerospace to consumer electronics.ertura aluminium die castingicommes to its application.r not