zinc die casting oem

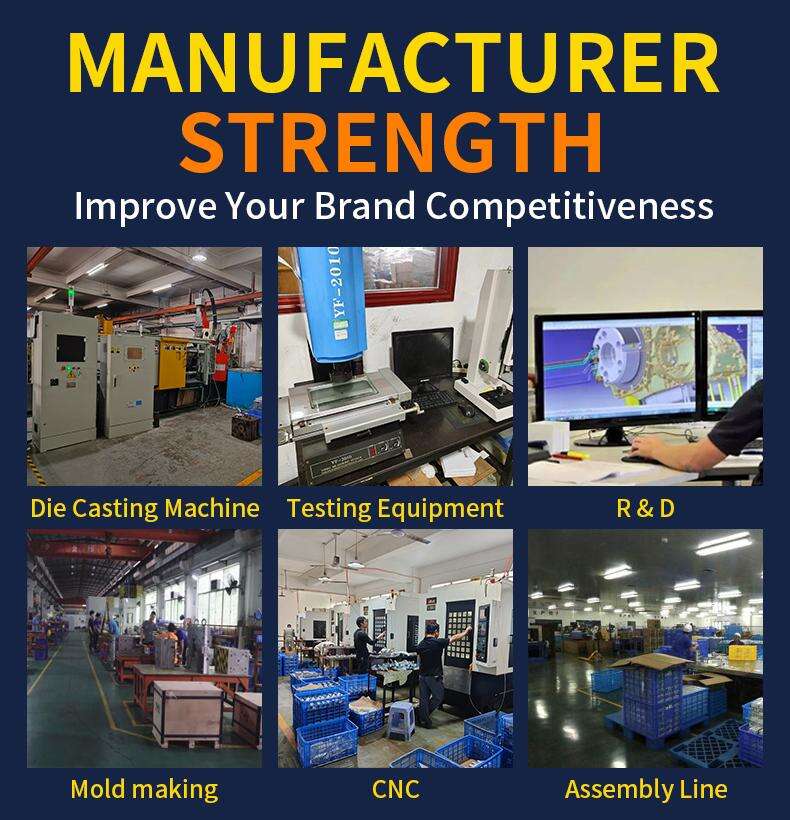

The OEM that does zinc die casting is an intricate process of injecting molten zinc alloy into a steel mold, known as a die, to get high precision components. Zinc die casting can create complex shapes, hold very close tolerances, and produce parts with fine surface finishes. Technological features--such as high-speed injection, precise temperature control, and automated robots--all serve to enhance the efficiency and quality of casting. A wide range of applications is found in these areas for the zinc die casting OEM process, from motorcycle parts to home electronics all the way to medical equipment and consumer products where strength along with good looks are important in equal measure.