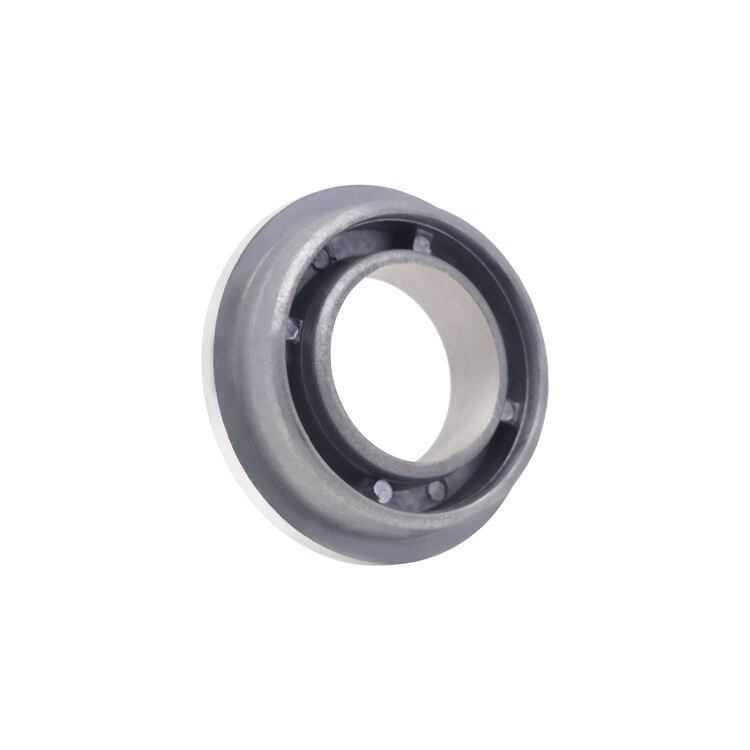

zamak die casting process

Zamak die castingis a precision manufacturing process that creates precision metal parts with fine detail and complex shapes. It mainly uses zinc-aluminum-magnesium-copper alloys. In this process,molten metal is injected under high pressure into a steel mold or die. Depending on its operating environment, the main purposes of of this processare parts with close tolerances, high surface finishes and ensuring that the parts remain of dimension consistent syntaxis. Die-casting process with zamak material has technologies that are generic across many industries as far as quality system automation is concerned; the cycle times are short so they help you push your fast production to even faster performances. It can also realize complex geometries in a single step. This process has become the preferred way for the automotive, electronics, aerospace industries and other fields to produce millions of parts like gears casings and connectors.