zinc die casting mould service

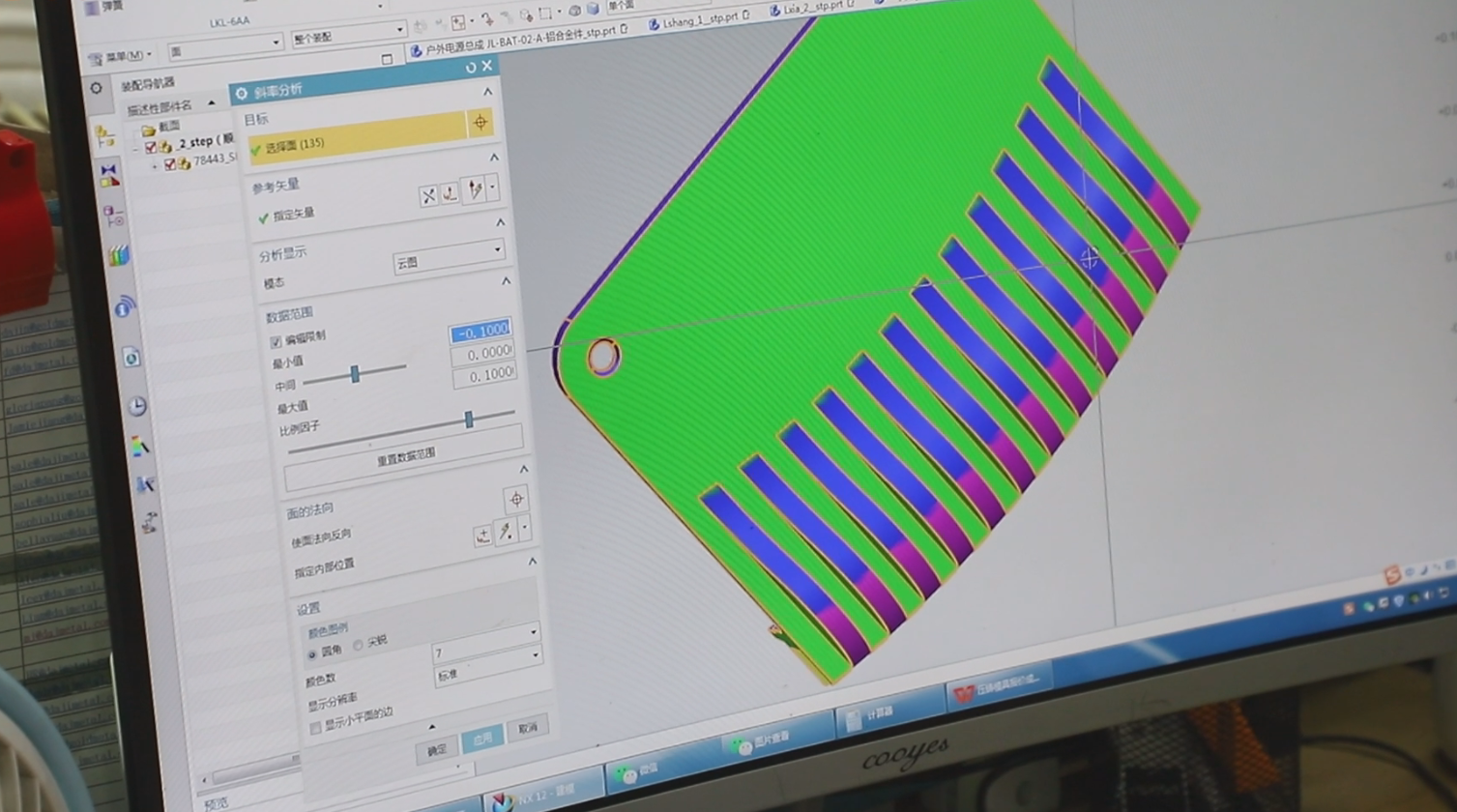

The service offered by zinc die casting molds operates with zinc alloys to manufacture precise and intricate metal parts. its main functions include producing complex profiles to high tolerances, as well parts of excellent surface finish quality. Technologically the Zinc Die Casting Mold has been designed with CAD and CAM systems which involve a mix of state of the art equipment, all types computers. These systems ensures precision-and gives consistent results in production. In industries such as automotive and consumer electronics, a mond used by this mold will go a long way to stopping pollution caused products from being released into the environment for long periods. An electric water heater's casing or external structure is a typical example. In environmental applications too such as mass-produced cars and electrical appliances, one also reaps the benefits of efficiency and durability For Every Purpose Including Refrigerators-Oil furnaces!