zamak die casting

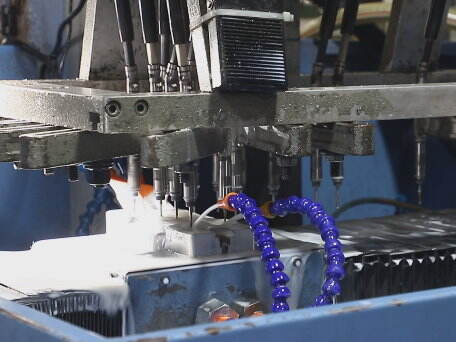

Zamak die casting is a precision manufacturing process used to produce complex metal components with delicate shapes and tight tolerances by injecting molten zamak alloy into molds at high pressure and temperature. That is to say, the main products of zamak die casting include intricate contours, small sizes in which all dimensions are closely related as well as a smooth surface finish. The technological highlights of zamak die casting include die casting machinery that is capable of continual high-speed production and therefore produces consistency in manufactured parts. In comparison, zinc-based Zamak alloys (which are composed of zinc, aluminium, magnesium, copper, and other additives) have good casting characteristics, excellent corrosion resistance and mechanical properties reduced to the utmost limit. With its outstanding economic efficiency and excellent end results, this process is widely used in such industries as automobile manufacturing and trade as well as electronic engineering, electrical machinery/heavy metal equipment production-emphasis technological sector under national high-end industrial development planning; these are all areas where high quality metallic materials are needed.