zinc die cast hardware accessories

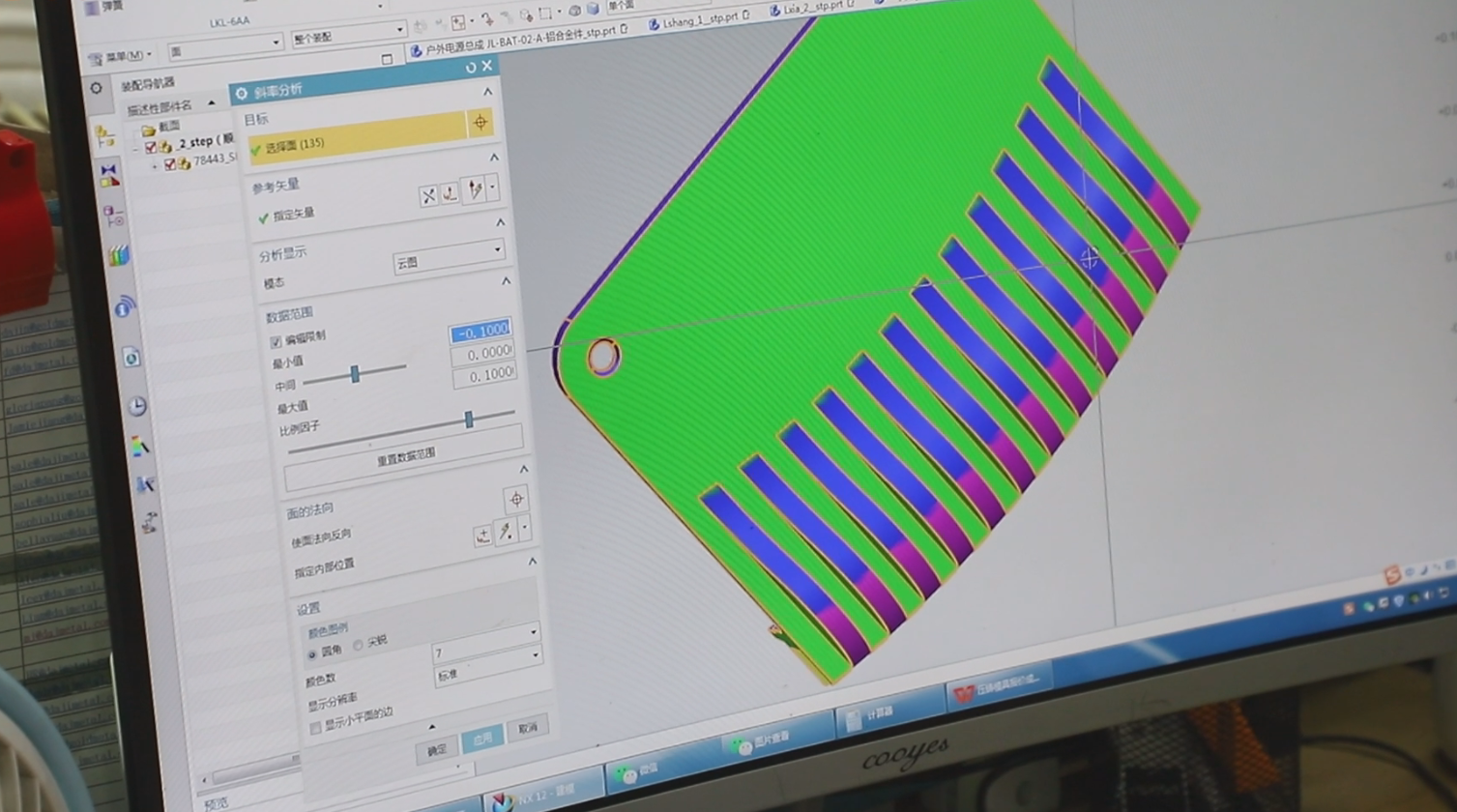

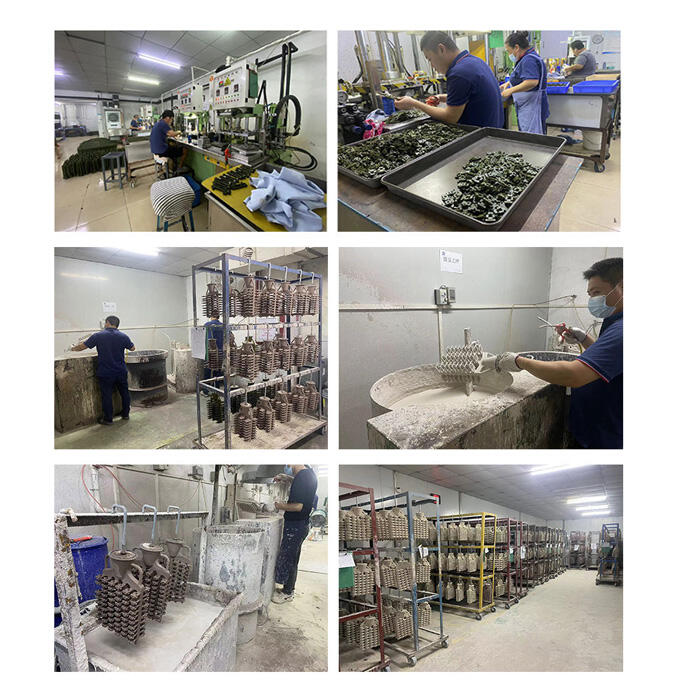

Our hardware accessories, made from machined zinc die cast, are precision-engineered components that are destined to last. One of their many main functions is being used as an anchor point for any piece in need of support, including approach bridge supports. Each features technological advancements like high-strength alloys and strict dimensional checks, which is suitable for complicate designs. With a wide range of different applications, frequencies and demands in different sectors such as cars unique lighting field:Architectural, Zenki combustion products producing methods must match the problem. Using zinc die casting we can get not only excellent corrosion resistance and a smooth finish to the screen surface, but also very good mouldability for complex parts when this process is used. In this way our hardware accessories ensure that solutions in manufacturing work well every time.