magnesium die casting

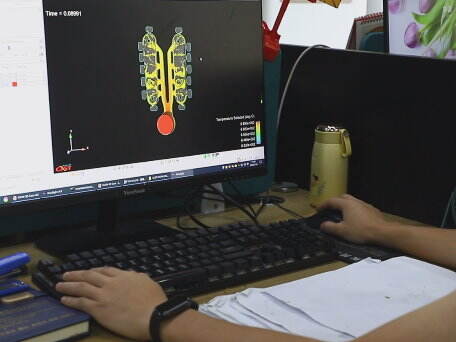

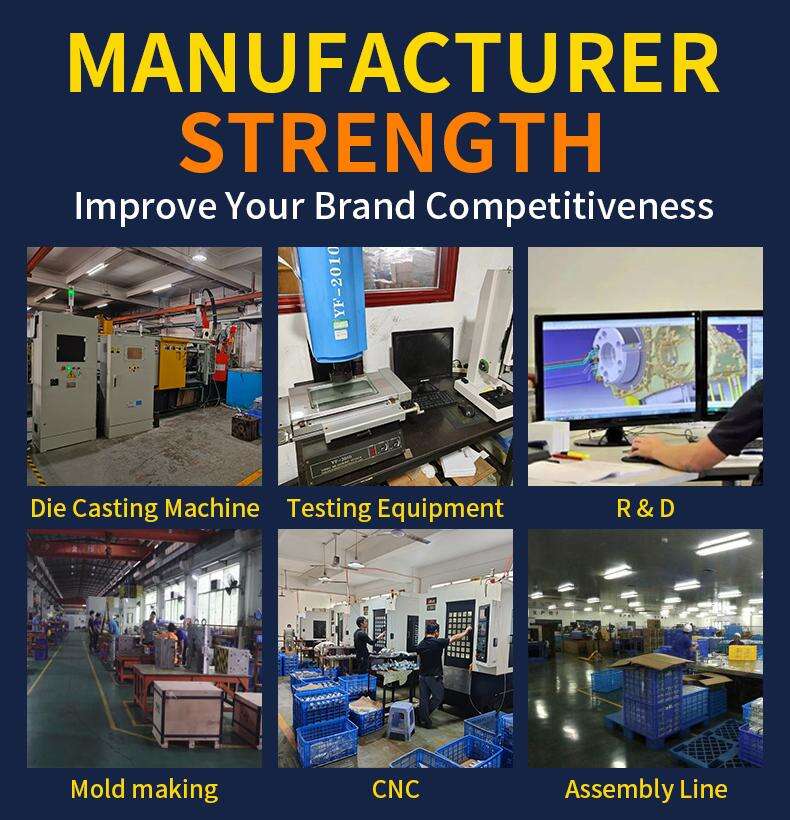

The advanced technology magnesium casting process, using which high-quality and complex magnesium parts can be made at high speed are made. This technique requires pouring molten magnesium under high pressure into a metal mold or die, and after it has cooled, extract the resulting shape. The main magnesium die casting practical functions are producing parts which have great integrity and dimensional accuracy. It distinguishes itself from other techniques in the ability to mold minute features, thin partitions and intricate shapes. Automotive and aerospace, electronics and medical equipment have all found a value in magnesium die casting. The lightweight but strong components are both alike crucially important for industry and irreplaceable by any other material except magnesium.