high pressure die casting companies

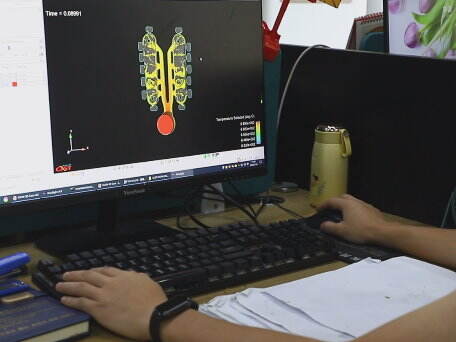

Many of these techniques require utilizing high-speed and high-pressure methods fot integrating molten metal into a mold cavity. These companies are typically responsible for manufacturing shaped metal parts that have complex shapes, have high precision and provide a beautiful surface finish. Die casting machines in the world today are comprised of higher degree technical features. These agencies have an advanced system, which automates all processes associated with die cast production, so part quality has improved. These new capabilities give complex parts used in different fields such as automotive and aerospace industries. They also work for electronics and medical-device devices where strong implementation of metal components is needed. The practice spans a wide range of applications and territories, and is necessary for durable yet beautiful metal products are wanted.