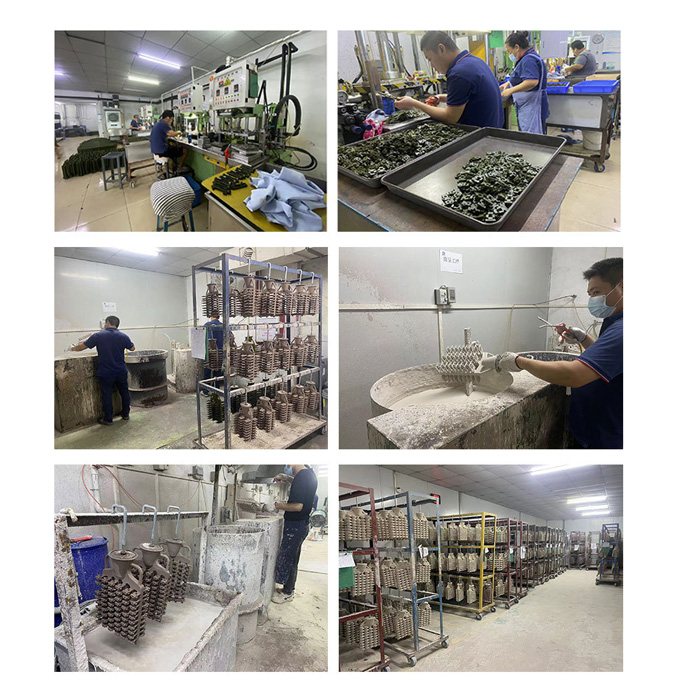

die casting lighting parts housing

Designed to encase and protect the internal parts of lighting fixtures, die casting lighting parts housing is a critical component of this industry. First it provides a robust and stable exterior within which sensitive electronic components cannot be damaged by environmental elements such as moisture, dust or physical force. High-precision molds and advanced alloys are now found in the housing, which not only give superior dimensional accuracy but also good structural integrity. The housing is also designed to effectively dissipate heat, this way light fixtures will have a long life. It includes automotive, aerospace and construction lighting.