die casting foundry

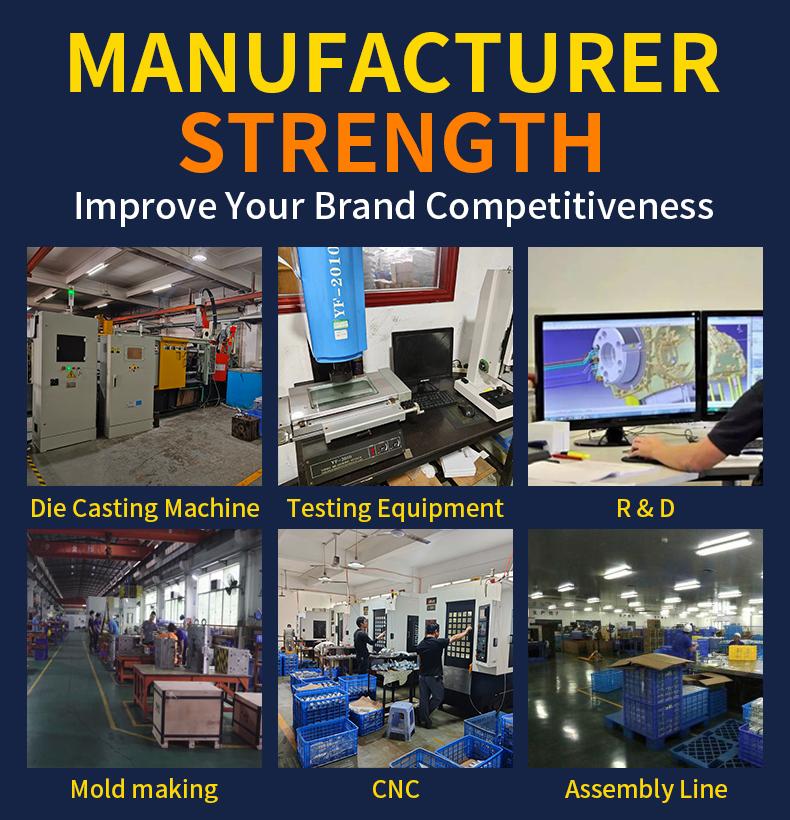

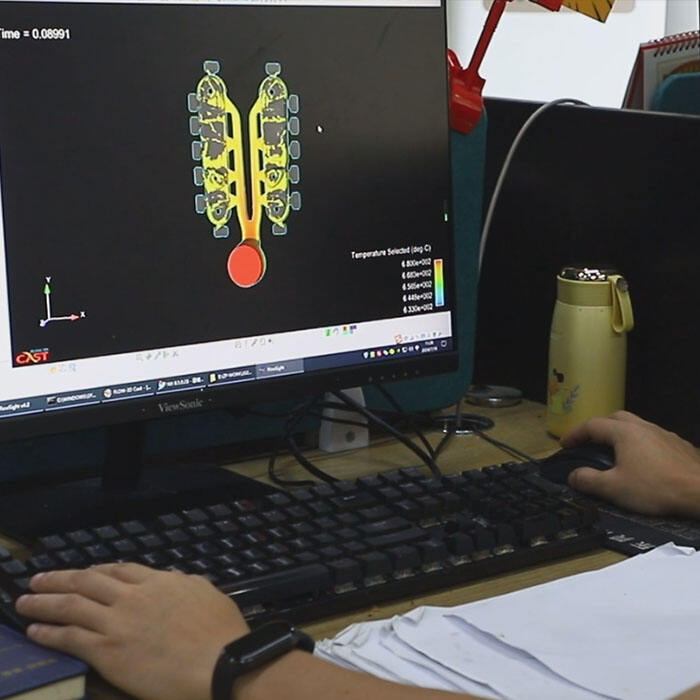

A foundry that does die-casting produces precision metal castings with dies or other means. Here is the traditional die-casting foundry, using fully automatic and advanced equipment to accurately and quickly turn molten metal into the shape required. Major functions of a die casting foundry involve melting metal for injection into a mold at high pressures that is then solidified; the final product is later ejected or cooled to room temperature. Technical features of a die casting foundry include automated control systems, exact temperature control, and advanced die design methods. Such characteristics make it possible to produce components of complex geometry with tight dimensional tolerances and excellent surface finishes. Application fields for die casting cover the range of industries including automobiles, aerospace machines and electronics, where a metal part must be both strong yet have fine detail.