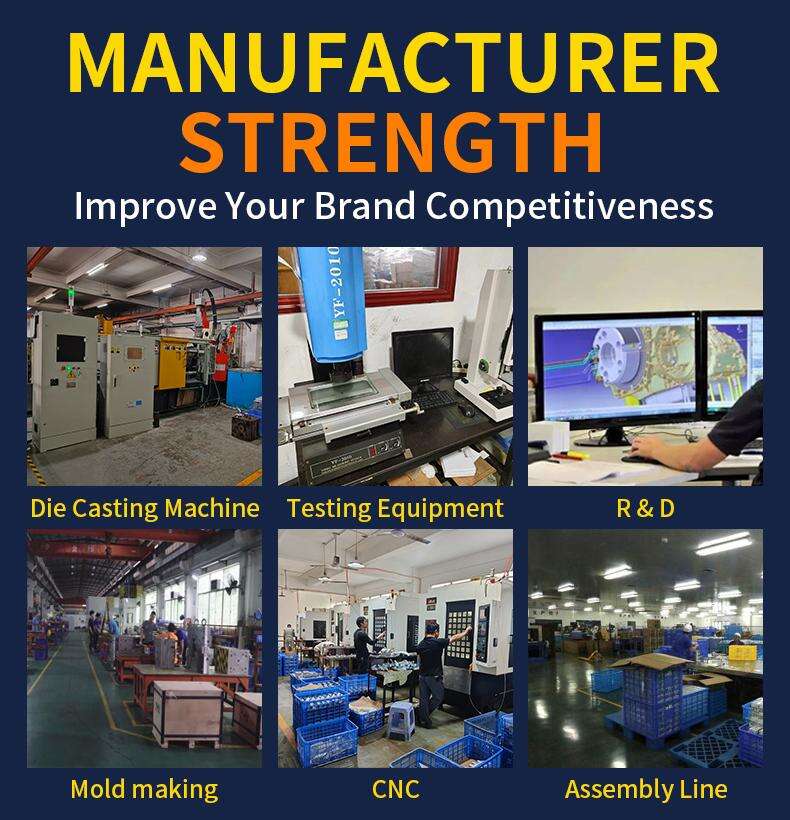

Customization and Innovation

The custom die casting die cast supplier durability remains one of its unique selling points. By working closely with customers to uncover special requirements and custom design die cast solutions The supplier sets itself apart. design-in Before production begins, this method Once customers find it beneficial for their products only themselves to use a diecast machine, the cost savings achieved through design rationalization and optimization mail now be enjoyed by every Tom, Dick or Harry without penalty of rework or assembly changes. Supporting customer services The supplier also assists its business partners in expanding their offering.Thus"That certainly helps," asserted Zhou. "By compressing the five steps into three, it reduces the overall time required

for model development," he explained.