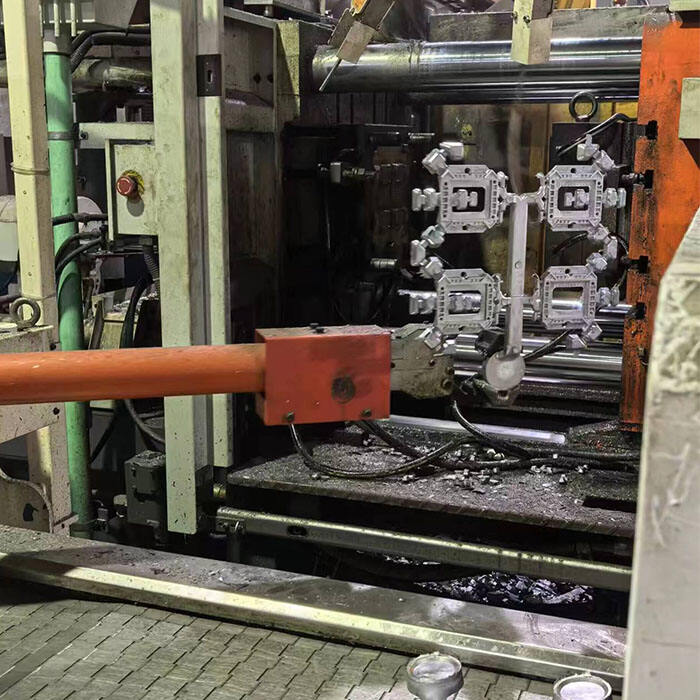

cast metal

Cast metal is a versatile type of material. It includes many different metals but they all have one thing in common: they start as unrefined ore which is then treated to produce cast elements for use in a wide range of industrial applications. There are couple reasons to use metal casting. First it can make parts than are difficult or impossible by traditional methods such as forming or cutting. Second, high accuracy, complex details and complex bosses can easily be designed. With its technical characteristics like high precision, intricate detail, and ability to make complex shapes that no other method can produce, casting is an indispensable procedure for manufacturing. Aluminum, bronze, steel, iron; each of these metals is available in cast type. Their uses cover everything from car parts and aircraft components to heavy machinery and household appliances.