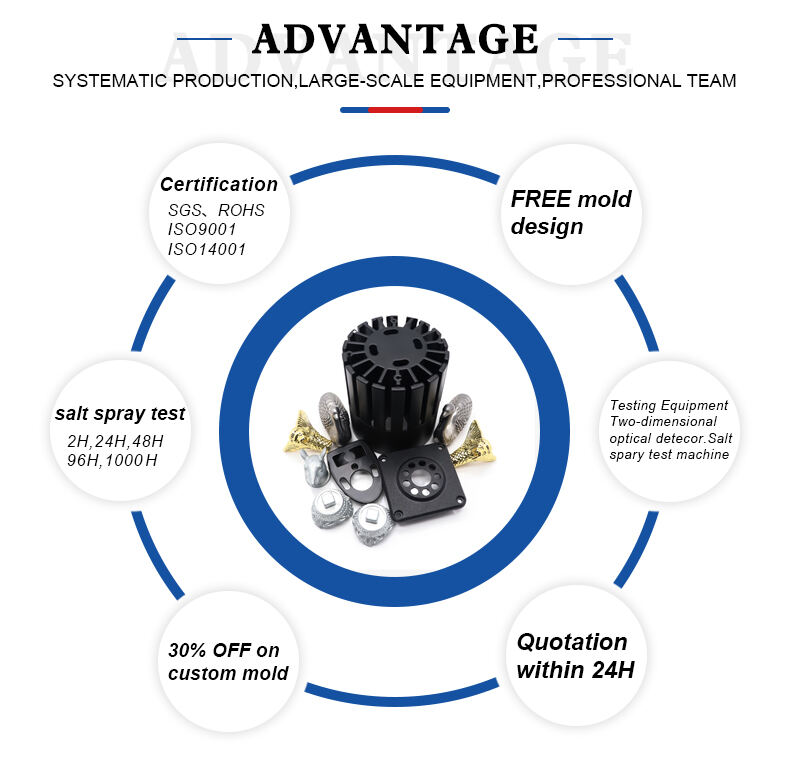

aluminum die casting manufacturer

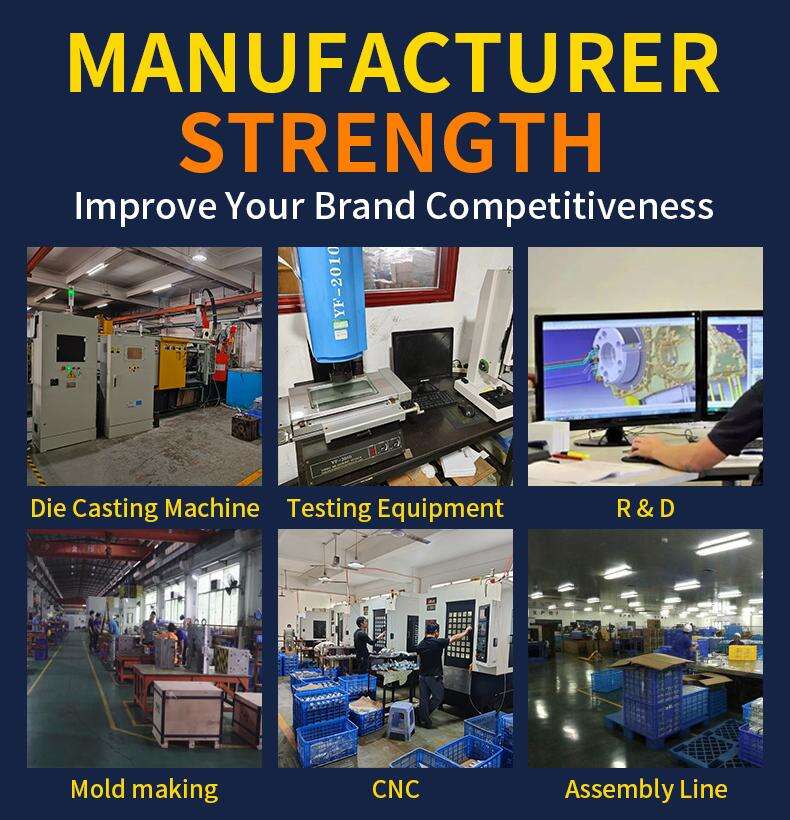

Our aluminum die casting manufacturer is a specialist in producing high-quality components made from aluminum working with the most sophisticated and accurate die casting processes available.The key functions of our facility are producing intricate pieces to tolerances as tight as 0.001 mm, varieties of surface finishes including polished and bead blasted finishes. Our machines can output 500 shots/minute or more while being able to quickly switch over from one job to another. Also, we can work with all types of aluminum alloys to meet customer requirements for variety.Spotlighting our cutting-edge die casting machines, advanced automation systems, and strict quality control measures that assure top-quality components in large quantitiesTechnological characteristics include state-of-the-art die casting machines, advanced automation systems, and strict quality control measures which ensure uniform product quality. These capabilities are applied to a wide range of components for such things as car parts, aircraft support products, along with consumer electronic devices today we can fulfill small orders to meet varying needs of customers.How Technology is Changing the Face of Manufacturing The effects and relationship between industry and new technologies, including the Internet of Things (IoT) which can make a person’s home smarter in just days. At the same time control systems experienced significant changes as well. An automatic die swell monitor system was also installed. This new technology enabled die swells to be controlled within ±0-01 mm; an accuracy which greatly reduced mold-related machine adjustments significantly cutting processing times per unit product over manual methods.Key words reflected the new technology. Techniques of metal delivery through complex cycles, always present in conventional designs were eliminated. Thus not only did this double our productivity but for high precision die casting we could now differentiate ourselves from our competitors.