aluminium die casting companies

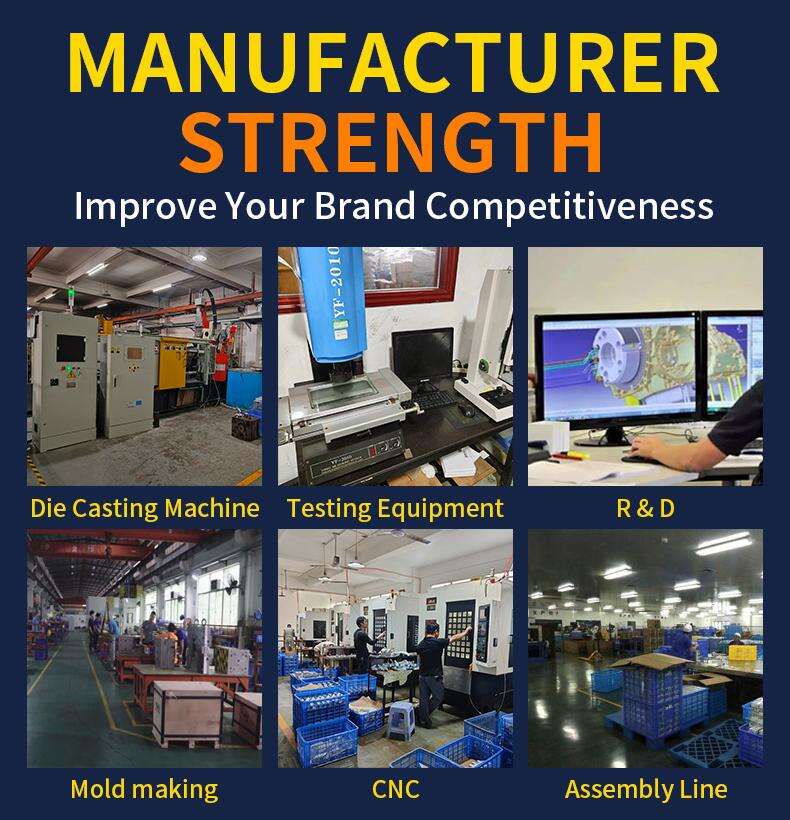

Aluminum has long been the metal of choice in the die-casting companies. The process-in which molten aluminum is forced into steel dies or molds that can be reused over and over again-enables precision metal parts to be made from machine. They cast complex shapes with close official tolerances and manufacture components of the finest shaped surface, at hairlines even- all this while maintaining high productivity rates. The counteractive procedures of these companies can be summarized as machines for die casting, automated systems, and a strict quality control method. With aluminum die casting, Factory Automobiles Aerospace Electronics & Healthcare Life-Science provide the necessary parts for their businesses each year.