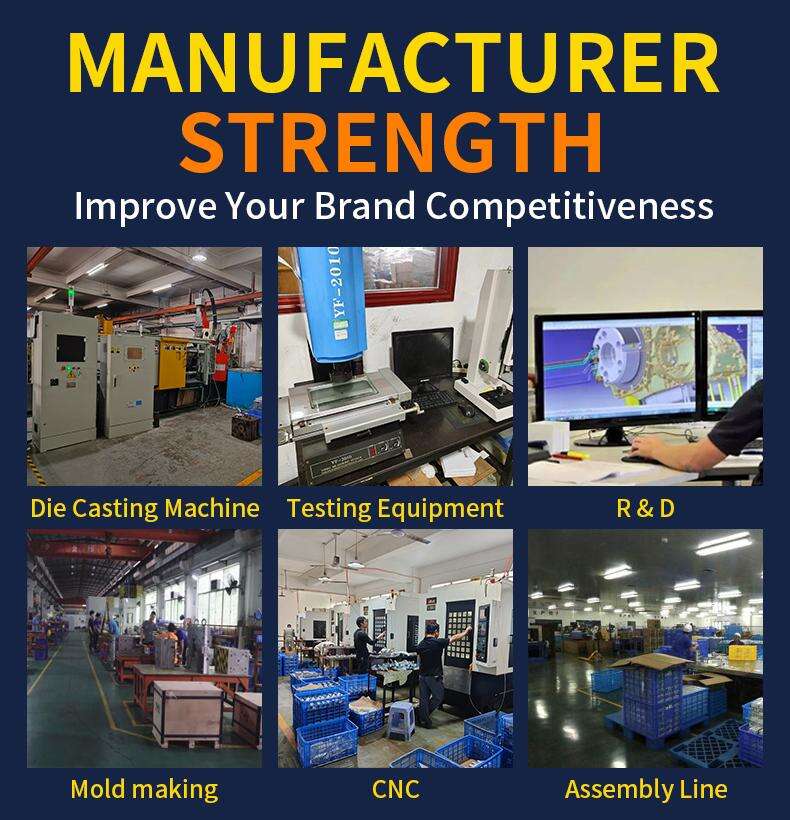

aluminum die casting metal shell

The metal shell is made from precision engineered die-cast aluminum die casting, which is used across a variety sources, process. It is made by a sophisticated die casting method that ensures structural integrity and dimensional accuracy as well as a precision feature exceeding most traditional methods of die casting forming. The primary functions of metal shells involve offering robust protection for the outer casing, the inner core elements as well as being an indispensable structural element in many devices and machines. Technological features of the aluminum die casting metal shell include its capability to withstand high temperatures, outstanding corrosion resistance and good mechanical properties. Thus these are desirable qualities for a wide variety of uses, from automotive parts to aerospace components and consumer electronics.