aluminium casting manufacturers

Aluminium casting manufacturers are leaders in producing top quality high performance aluminum components through cutting edge processes of casting.

These manufacturers main functions include design, mapped out silhouettes and castings for goods that are used in industries far beyond the looks industry.

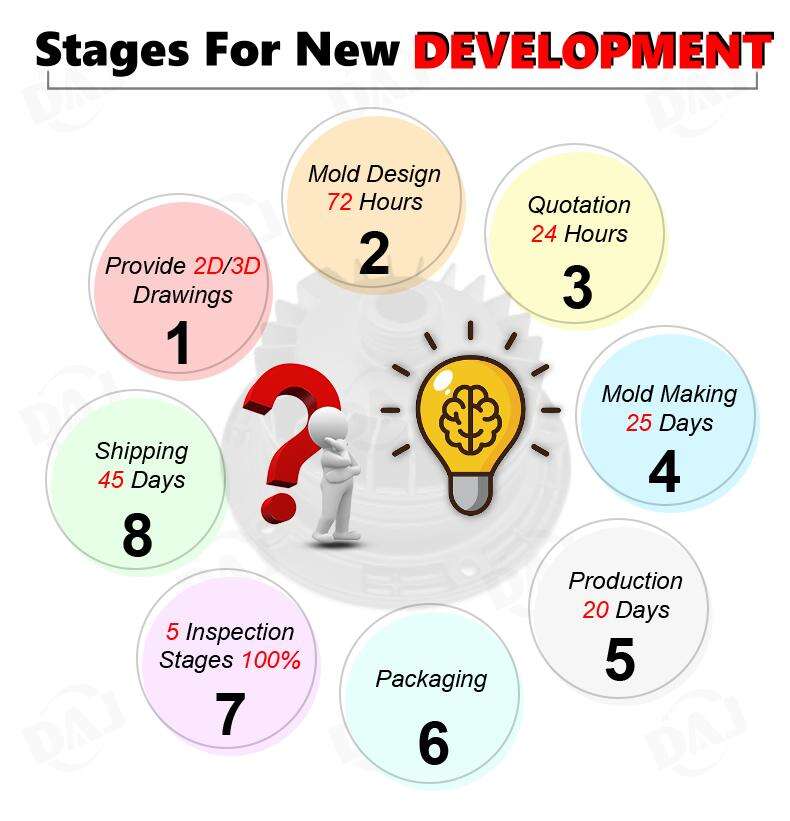

Through their employment of advanced technological features such as precision molds, automated casting lines and strict quality inspection processes the production manufacturers guarantee parts to meet the letter of customer demands.

Aluminum casting is versatile, allowing shapes more complex and thinner walls. This makes it suitable for a variety of applications including automotive parts and aerospace components as well as electronic devices or consumer goods.