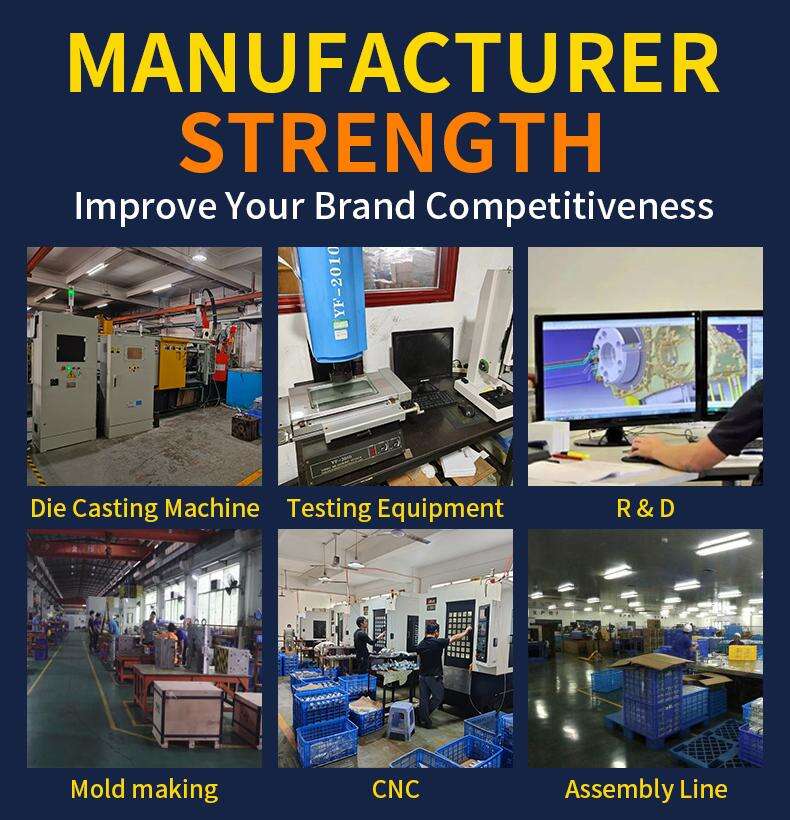

aluminium casting companies

Aluminium smelting companies are dedicated to transforming the molten metal into forms you want by using casting methods. To ensure the accuracy and quality of the machine process depend on cutting-edge technology, these enterprises adopt advanced technologies that assure precision and quality in manufacturing. Mainly including mold design, aluminum casting, and castings finishing.For example, computer-aided design (CAD) and computer-aided manufacturing (CAM) technology make operations accurate, efficient. The production of aluminium castings owes to their lightweight, corrosion-resistant, and high strength-induced properties is dispersed to industries such as car manufacturer, aerospace materials supply constructors or electronic manufacturers.