precision zinc gravity die casting parts housing

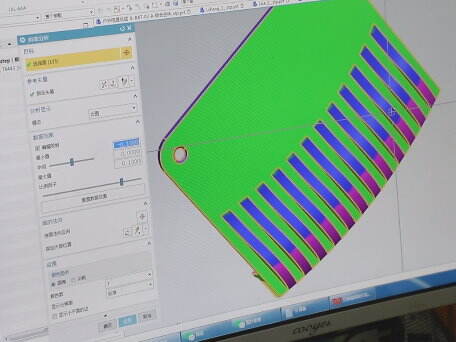

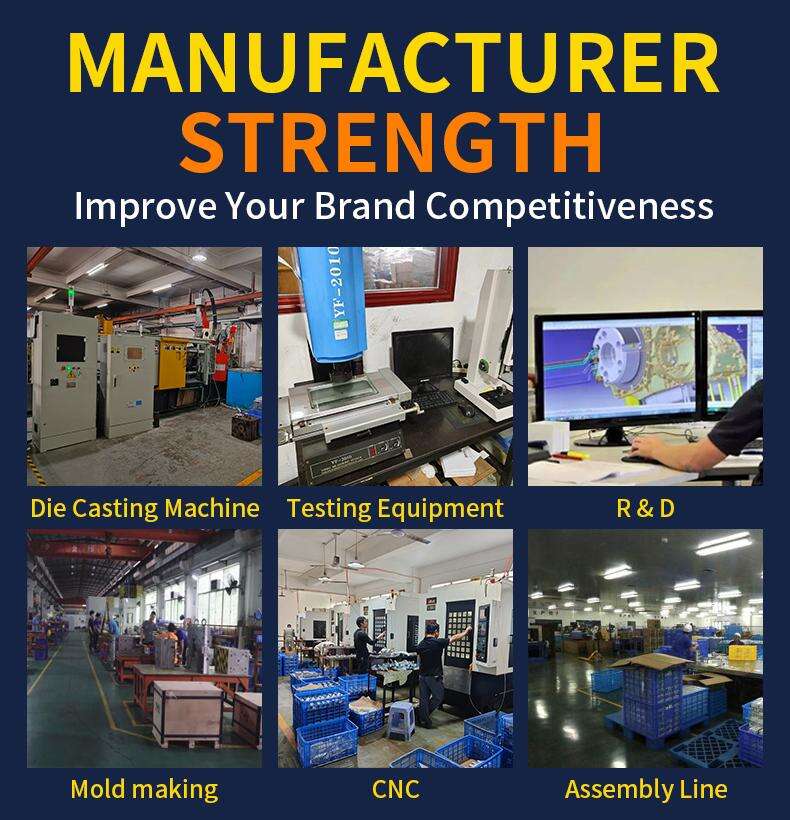

This precision Gravity die casting zinc parts housing has been carefully crafted, sturdy to provide robust protection and support for inside workings. Its main functions include encasing and protecting sensitive parts, ensuring structural integrity, and making satisfactory operation possible for a variety of devices. Technological features of this housing include high precision, consistent wall thickness, and good surface finish. All of it comes from the advanced technical processes used in zinc die-casting. The housing covers a wide range of applications in sectors such as automotive, electronics and general engineering where quality is the first consideration.