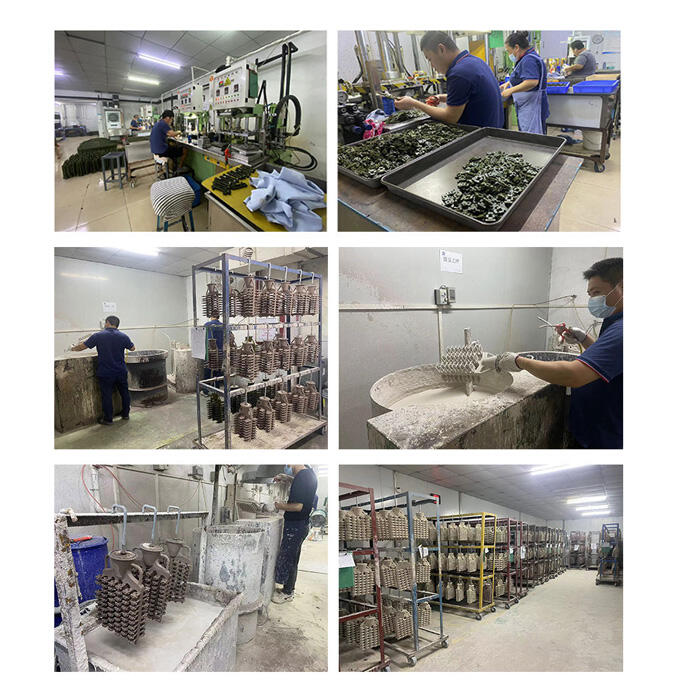

light heat radiator die casting

Light heat radiator die casting is complicated technology which enables radiators to be both light and efficient heaters. These well radiator could escape heat fully, it is all industry, special in cars, the full range of communications and electronics. The principal influences are heat transfer, giving the cooling system an extra boost and maintaining ideal temperatures for various kinds of equipment. One technological feature of the light heat radiator die casting process is the use high pressure die casters that ensure both precision and the integrity required. Advanced aluminum alloys are usually used because they enable a combination of high thermal conductivity and low weight. The result is a product which is sturdy, with high precision tolerances and can be easily integrated into complicated systems. There are applications in a wide range of industries, especially where good heat management is essential in exrtreme environments and for reliability.