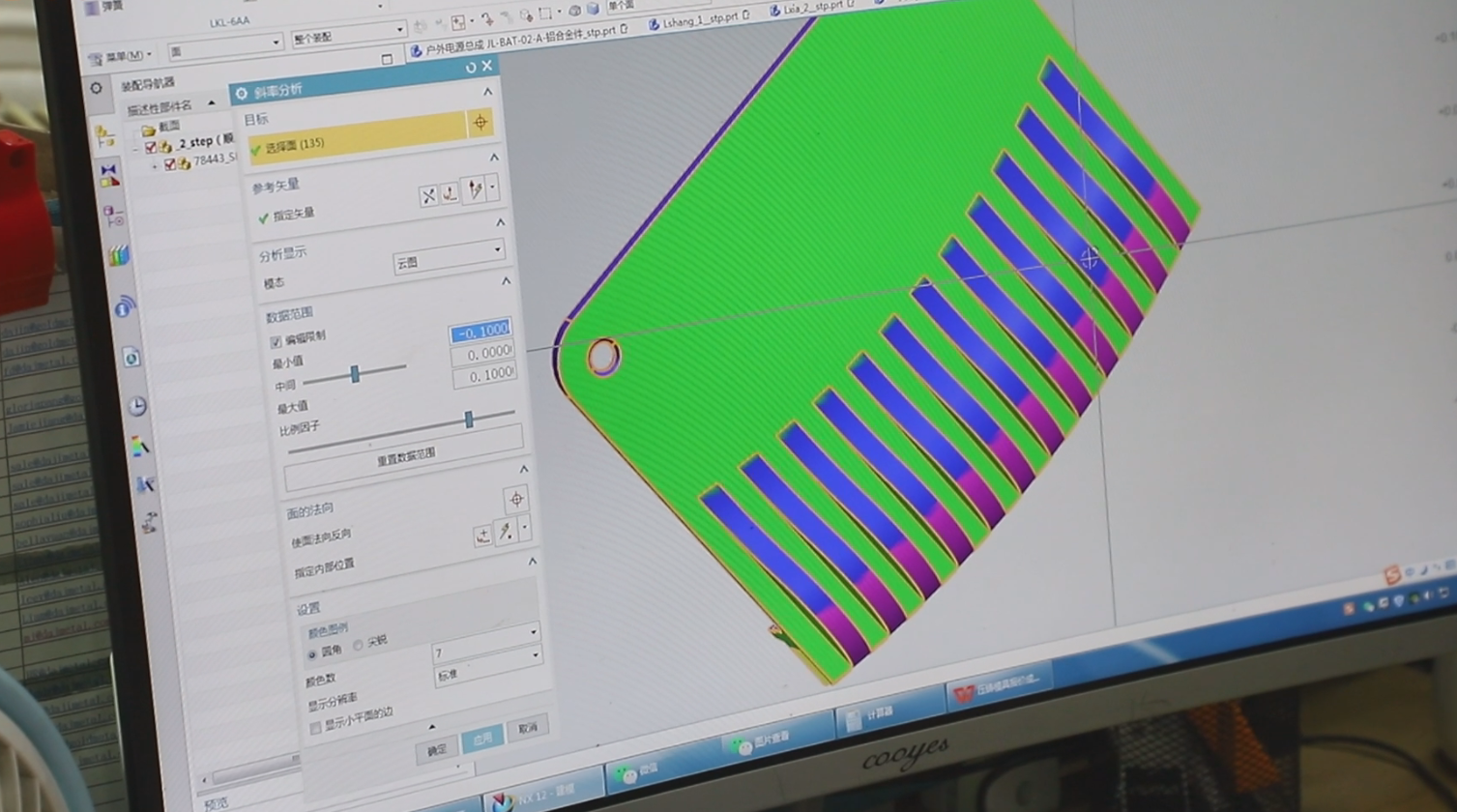

Precision and Repeatability

However, with cast products & zinc die casting precision, and then repetition is visible by you system. This ensures that all of the many identical items which are produced are the same, an essential feature for industries requiring a consistent-quality product in bulk. Thanks to this precision, the final product not only gains in functionality but also becomes more economical in terms of material use and assembly work--all things that help annual savings to grow for manufacturers.