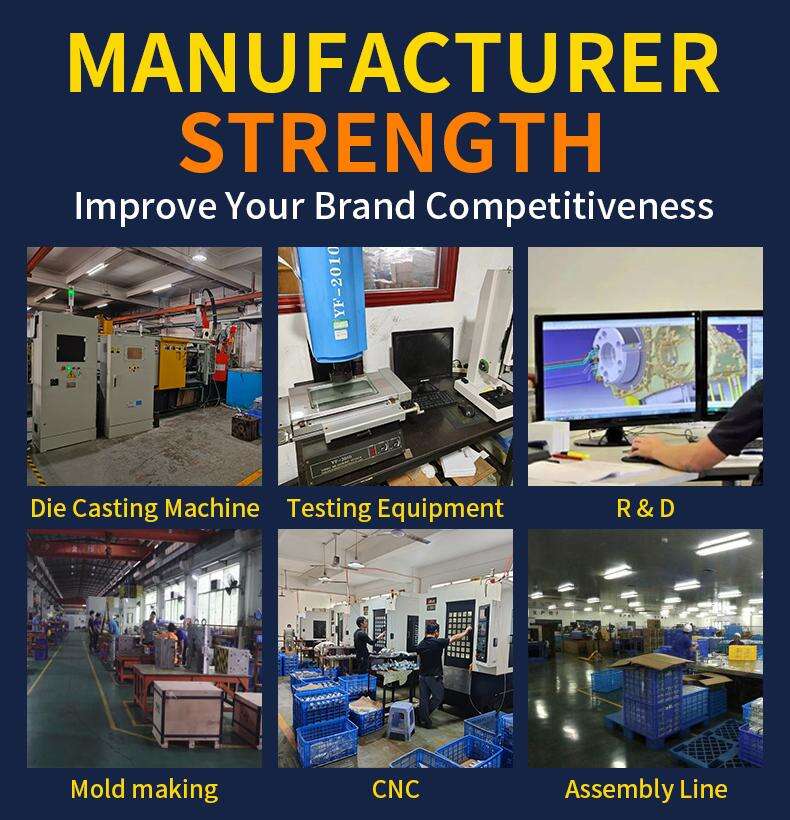

cast aluminum parts manufacturers

The casting of aluminum is the crux of work for cast aluminum parts manufacturers. What provides these manufacturers with a certain prominence, is their functional range: intricacy is a common trait of the many parts and shapes that cannot be achieved through traditional machining techniques. Advanced casting techniques, precision machinery and strict quality control processes are the technical features ofit.These manufacturers' products are applied in areas from automobiles to aviation or construction to consumer goods. They are known for their long service life, resistance to corrosion, high temperature performance and so on. It is precisely these qualities that make cast aluminum parts indispensable in countless industrial and consumer products.