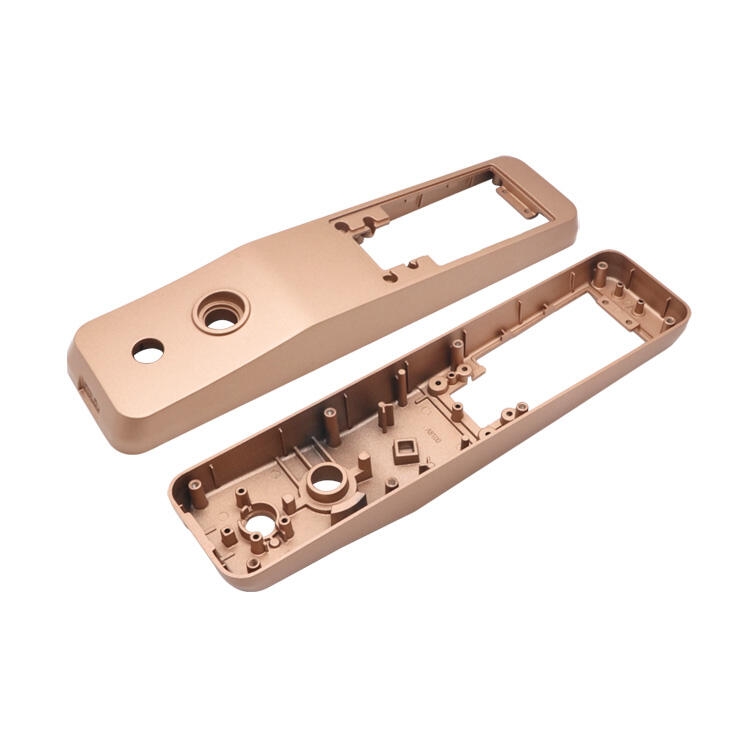

aluminium die casting components

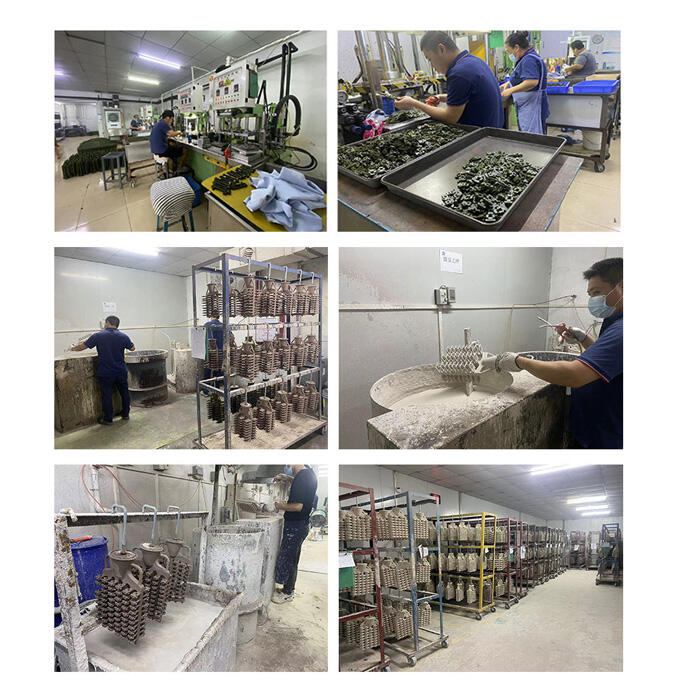

Aluminum die-casting components are precision-engineered components. Produced through a very complicated process, molten aluminum is injected under high pressure into a metal die or mold. These components are known for the finely detailed and complex geometric shapes that are difficult to produce by traditional methods of manufacturing. More specific applications in automobile seat frames and related components, air-conditioner systems, camshafts, gear boxes etc., and aluminum die casting components have made rapid inroads. Aluminum die-casting metal also has the main functions of: providing structural support; encapsulating electric and electronic parts in cases for instance battery cells (Pb-Ag), and so forth; serving as an attractive add-on. With technical features like high dimensional accuracy, superior surface finish quality and no need to punch another name out literally but create complex shapes, they are an excellent addition to various industries. They have also been applied in automotive vehicles, fuel dispensers and other facilities where durability, light weight properties and resistance to rust are important.