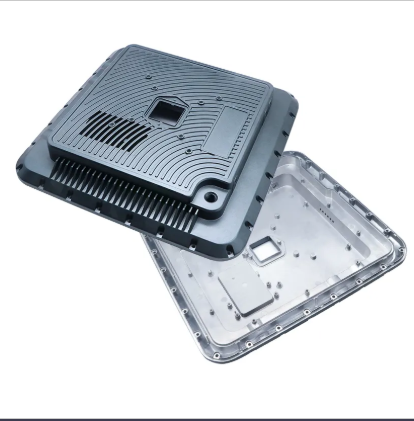

Precision Mold Design Considerations

A proper design of the high precision mold cannot be underestimated in the case of superior surface quality in zinc alloy die casting. The design of the mold also has to consider size, materials (steel or aluminum), and finely tuned engineering to deliver good results. For example, choice of the type-of mold material can influence the surface texture and the toughness. Many molds are made of steel which is stronger than aluminum and, in general, yields better finishes. In the field of precision molding, molded surfaces have shown better part quality, where defect rates are minimized in carefully designed molded articles. The use of cooling channels with the mold helps express high-quality results by favorably promoting cooling. These channels are becoming more and more frequently designed using the technique of Computational Fluid Dynamics (CFD), to optimize the thermal management and obtain a uniform surface quality.

Controlling Melt Temperature and Injection Speed

The melt temperature has a significant effect on surface finish of zinc alloy. The desired temperature range provides a perfect balance of fluidity and hardening to minimize surface defects. Research indicates that when the temperature is kept within the range of 420 °C and 440 °C, improved quality finishes are obtained. Injection rate also plays a major role in appearance, and high rates can cause flow lines or other defects in the surface. Comparative data on various injection-speed levels indicate that lower speeds result in better finishes. Producers are able to adjust these values during production to obtain the correct melt temperature and injection velocity. Success stories in the industry adopting such practices highlight how accuracy is key for quality surface finishes.

Vacuum-Assisted Die Casting Advantages

Due to the vacuum-assisted die casting process was claimed to have advantages for zinc alloy production, such as the reduction of gas entrainment and the improvement in surface finish quality. This process reduces air pockets and results in a better-looking product. It has been shown statistically that by using vacuum technology, the defect rate can significantly be reduced, providing for a superior product appearance Package Includes: 1 x 3D Sublimation Machine. Furthermore, not only product quality but long-term contribution such as cost reduction of less loss and up of manufacturing efficiency also can be expected in vacuum assistance casting. Improved quality results in reduced rejects, which means lower production costs and increased profitability.

Mechanical Deburring Methods

MANUAL DEBURRING is so important for the finish of zinc die castings. These processes make it possible to get rid of burrs, which are unwanted projections on casting surfaces that can influence the appearance and effectiveness of the part. Tumblers and vibratory finishers are frequently used for mechanically deburring parts with limited geometries and designs while hand tools such as files and grinders can be used in much more complex parts. That’s the best way to apply powder – right gun for the size and geometry of the part applied consistently for the best results. It has been reported that surface roughness can be reduced smoothly from 30% to 20% when proper deburring is achieved for the nobles sand casting and therefore an excellent product quality could be achieved.

Chemical Cleaning for Oxide Removal

Chemical cleaning is the acid cleaning of the surfaces of Zn-coating alloys and is essential to giving a good finish. One approach is by use of chemcials, e.g. acids and bases, which are capable of dissolving oxides without attacking the metal beneath. Industry analysis has proven that these chemicals are effective regarding treatment of surfaces for subsequent finishing process such as painting or electroplating. It is necessary to follow the safety principles by protecting the worker and the environment, carefully selecting people who will wear the PPE (personal protective equipment) and checking the place for good ventilation. Besides, the recycling or neutralization of chemical waste has to be taken into account by the manufacturers in order to satisfy environmental laws.

Abrasive Blasting for Texture Uniformity

Injection Blow Abrasive blasting is a common process of engineering homogenized surface texture of zink alloy parts. There are different ways that texturing can be done and one process is to projectile shoot abrasive materials like sand or glass Beads at a very high speed on the surface of the part. There are reports of improvements to surface quality when materials are abraded, with greater uniformity and the removal of imperfections. It is important to select the right blasting material as different blasting media have different effects on the surface profile. Finer abrasives, for example, can create a more polished finish, while coarser abrasives may be applied to materials that are rougher in nature. The surface finish quality can be greatly increased by selecting the proper abrasive to suit the specific purpose.

Electroplating for Corrosion Resistance

Electroplating brings with it substantial benefits by improving the resistance to corrosion of the zinc alloy through metallic coating. The metal has a layer placed to deposit this coat, which is aesthetically appealing and resistant to elements. Standard coating thicknesses are varied, and often are in the range of 5-10 micrometers, resulting in extended life of parts. Automobile Use Now let me give your an example that in automotive industry electroplated parts always keep their well-sementic state by you can see clearly in the pictures showing their tenacity properties even if they are put through harsh conditions. Besides, studies show that the lifespan of zinc components can be increased to as much as 300% through electroplating.

Powder Coating Applications

Powder coating is a favored method of enhancing the properties of durability and color of the surface of zinc alloy. Unlike conventional liquid paint which is applied wet and followed by drying, the powder coating process is dry finishing which utilizes a very fine powder. Besides, the procedure not only improves the wear and chemical resistance of the component, but also provides several choices of colour which do not bleed and drip. The long lasting protection of powder coating is evidence based, with industry stats which see powder coated product 50% more durable when compared to liquid forms. Benefits to the environment are also significant, with powder coatings producing far less volatile organic compounds (VOCs), meaning they are the safer option for manufacturers.

High-Precision Polishing Workflows

High-precision polishing is a prerequisite to top-class surface quality of zinc parts. This process consists of employing instruments and agents in a process to perfect the texture, adding to the visual quality and functionality of the device. Processes, too – a central motor of the industry revolves around processes – such as rotary buffing and vibratory finishing are also pivotal, running the amazing before and after stories the industry showcases through electronics manufacturing case studies. The degradation of common polishing material is comprised of rouges and oxide abrasives, which all provide a different contribution to the surface finish. Employing these techniques means producers can reliably conform to strict quality requirements to meet the finish and performance criteria now expected from zinc alloys.

Non-Destructive Testing Methods

Non-destructive testing (NDT) techniques are of great significance for the estimation of the surface quality of the zinc die castings without destroying them. These techniques enable effective detection of internal or surface defects that might cause poor quality of the final product. Primary NDT methods include ultrasonic, radiographic and magnetic particle tests. The methods assist in the establishment of industry standards that reduce the occurrence of faults in zinc die-cast components. In addition, NDT can be used in a quality control loop that will not only verify a part's integrity without destroying or altering it, but will also help to optimize production processes, thereby enabling products to be delivered to market more quickly and at a lower cost.

Surface Roughness Measurement Standards

The surface roughness measurement norms are necessary for consistent and high quality of ZA components. The use of Ra or Rz values allows manufacturers to set production guidelines based on universally recognized parameters, enhancing customer satisfaction. Profilometers and 3D scanners are widely used for an accurate measurement. In the automotive and aerospace industries, the introduction of these standardised measurement methods has led to substantial leap in product performance, customer acceptance and satisfaction.

Defect Prevention Strategies

The quality of a surface finish can be particularly affected in that defects prevention techniques are applied during processing. There are other methods such as process optimization and the use of quality control checklists to minimize surface defects, which include porosity and warping. Industry input also emphasizes that good practices such as better mold design aid in controlling defects. The objective is to monitor the improvement figures and the defect rates and measure production improvements with hard facts and numbers that will assist you in producing better zinc castings and less scrap.

Laser Surface Texturing

Laser surface texturing has been developed as a novel approach to improve the surface properties of zinc alloy components, especially the surface adhesion and the wear resistance. The method uses laser beams to generate micro-patterns on surfaces, thereby improving mechanical properties. For example, according to an article published in the Journal of Materials Processing Technology laser texturing can greatly enhance the properties of coated surfaces and improve adhesive strength and service life of such surfaces. In the case of the use of laser surface texturing in production activities, a tradeoff between these parameters plays an important role in the overall performance. Although the initial cost of the laser equipment is high, the long-term payoff of cost savings in wastage and a reduction in failure rates as well as increased product quality often compensates for it by giving a competitive advantage above that cost in industries utilizing manufacturing.

Nano-Coating Developments

Nano-coating is a major progression in dealing the zinc alloys because of the enhanced surface life, resistance with adverse environment etc. They form ultra-fine layer coatings on metal surfaces and provide improved corrosion protection, mechanical stability etc. According to the findings, The ZN with/without nano-coatings was presented to be more ecocnomical than the conventional coatings,it was able to resist hazardous conditions approaching those of the traditional coatings. One other work reported that the salt spray resistance of ITO films exhibited great improvement, demonstrating excellent properties in severe environments. In the future, advancements in nano-coatings promise to further concentrate on specialization for applications related to zinc, ultimately lowering costs and making manufacturing lines more accessible, while still raising the bar on performance.

Automated Finishing Systems

Automation of finishing processes changes the speed and quality of the manufacture of zinc components. Cobot solutions combine cutting-edge robotics and controller design enabling consistently high surface quality with dramatically reduced production times. For example, factories have implemented these systems have reported significant improvements in surface consistency as a result of fine tuning finishing parameters. However, automatic completion systems have drawbacks, expensive purchase costs, and operating and servicing of the machines require well-trained technicians. While the above noted challenges remain as technology progresses, modular system options and factory training make automation increasingly attainable for the zinc alloy industry to realize the additional benefits of increased production efficiency and consistent product quality.

FAQ

What are the benefits of using vacuum-assisted die casting for zinc alloys?

Vacuum-assisted die casting reduces gas entrapment, enhances surface finish quality, lowers defect rates, and offers long-term benefits like cost savings and improved manufacturing efficiency.

How does controlling melt temperature affect zinc alloy die casting?

Melt temperature critically influences surface finish by balancing fluidity and solidification. Maintaining the ideal temperature range minimizes imperfections, resulting in a superior surface finish.

What role does electroplating play in zinc alloy corrosion resistance?

Electroplating enhances zinc alloy corrosion resistance by applying a thin metallic coating, which adds aesthetic appeal and protection against environmental elements, significantly prolonging component lifespan.

Why is abrasive blasting used in zinc alloy component finishing?

Abrasive blasting is used to achieve uniform texture and remove imperfections, significantly enhancing the surface quality of zinc alloy components by choosing the correct abrasive type.

What are the advantages of nano-coatings for zinc alloys?

Nano-coatings offer improvements in surface longevity and resistance to environmental conditions by forming ultra-thin layers that enhance corrosion resistance and mechanical stability.

Table of Contents

- Precision Mold Design Considerations

- Controlling Melt Temperature and Injection Speed

- Vacuum-Assisted Die Casting Advantages

- Mechanical Deburring Methods

- Chemical Cleaning for Oxide Removal

- Abrasive Blasting for Texture Uniformity

- Electroplating for Corrosion Resistance

- Powder Coating Applications

- High-Precision Polishing Workflows

- Non-Destructive Testing Methods

- Surface Roughness Measurement Standards

- Defect Prevention Strategies

- Laser Surface Texturing

- Nano-Coating Developments

- Automated Finishing Systems

-

FAQ

- What are the benefits of using vacuum-assisted die casting for zinc alloys?

- How does controlling melt temperature affect zinc alloy die casting?

- What role does electroplating play in zinc alloy corrosion resistance?

- Why is abrasive blasting used in zinc alloy component finishing?

- What are the advantages of nano-coatings for zinc alloys?