die cast mechanical hardware fittings

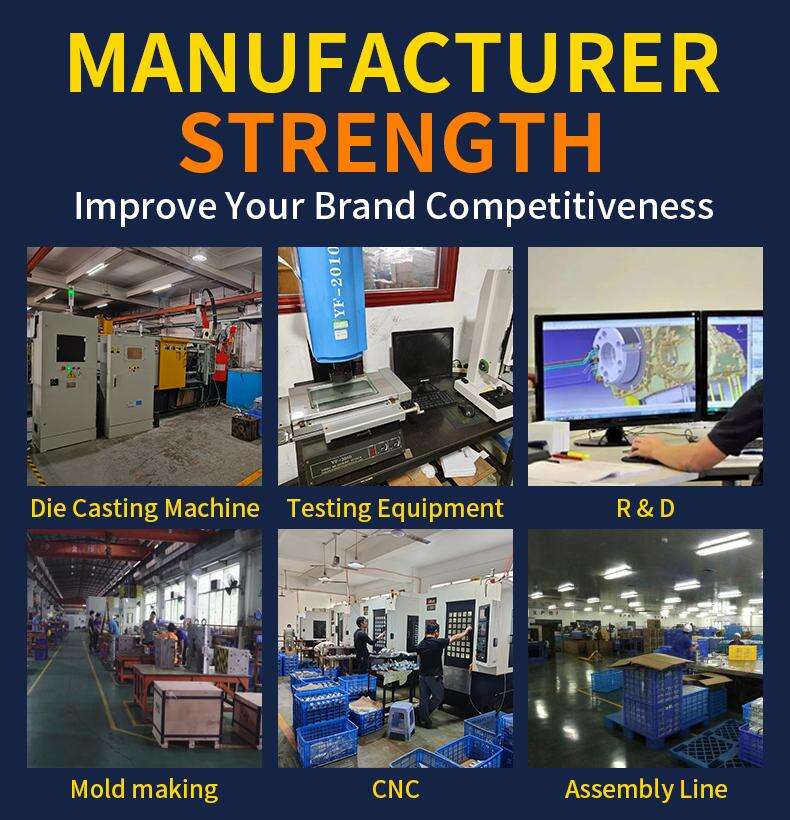

Die cast mechanical hardware fittings originated with the production of mechanical equipment and devices. Through the scope of these physics-based components, there are many functions: they link things up or fasten them together and adjust structure off centre to allow for balancing of forces in space. Also they are responsible for stability that is critical Stability or durability. With the use of advanced process die-casting, Techi mix boasts high precision shapes and dimensions which are perfectly tailored for their specific applications. These science-based Tangibles include excellent tensile strength, corrosion resistance Long life at non- Oceans temperatures and high usability. Such hardware components are closely integrated onto automobile, aviation, electronics and general machine manufacturing, each industry that asks for reliability PerformanceCannot go unmet.