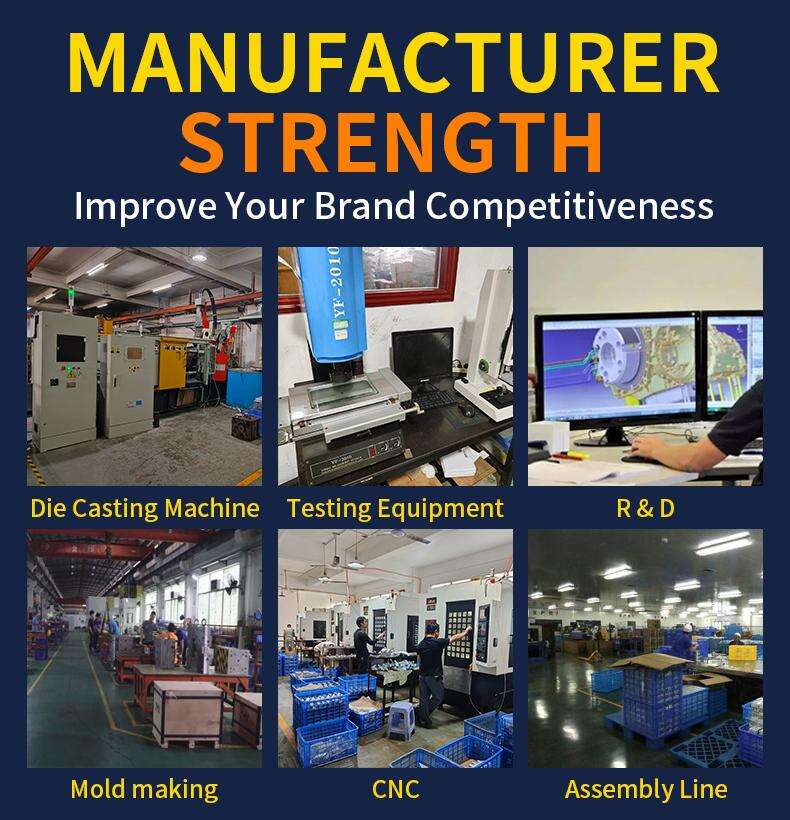

die cast factory

The Die Cast Factory is a state-of-the-art manufacturing facility specializing in precision die casting of metal components. Forming metal parts high quality and intricate shapes result from molten metal being poured into metal molds. Die Casting high-pressure casting machines, also known as forcing machines, give this effect to achieve the complex shapes. A number of technological features unify the factory as they include automated systems, most up-to-date CNC machines and the strictest requirements for every stage of quality control. Die cast products are used in multitude industries, including automotive, aerospace, electronics and so on. As such diverse manufacturing provides components vital for variety Industry's processes.